Analysis of economic effects and environmental effects:

Waste tyres/waste plastics/waste rubber/waste acrylic/domestic garbage/medical garbage/oil shale/other waste matters

The easiest disposal method is to landfill and incineration. Landfill occupies too much precious land resource. Since fuel oil refining equipment is developed from waste rubber and waste plastics, this equipment has become a common research and topic governments at all levels pay much attention to. It can not only save resources for human, but also creates new type energy. With simple workshop, rich raw materials, low cost and high profit, this equipment only covers an area of 450 square meters. The recycled fuel oil is applied to many fields. Customers at home can recover all costs within three months. Customers from south-east Asia can recover all costs in one and half months. Take waste tyres as example to calculate profits:

Summary: daily profit: 8240 yuan;

Monthly profit: 164,800 yuan (20 days)

Annual profit: 1,648,000 yuan (10 months)

Collection, transportation and storage system: this system conforms strictly with national standards for dispoal of wastes. it mainly consists of collection, transportation, measurement, discharge, temporary storage and sterilization devices.

2. This process is not only easy, but also friendly to environment.

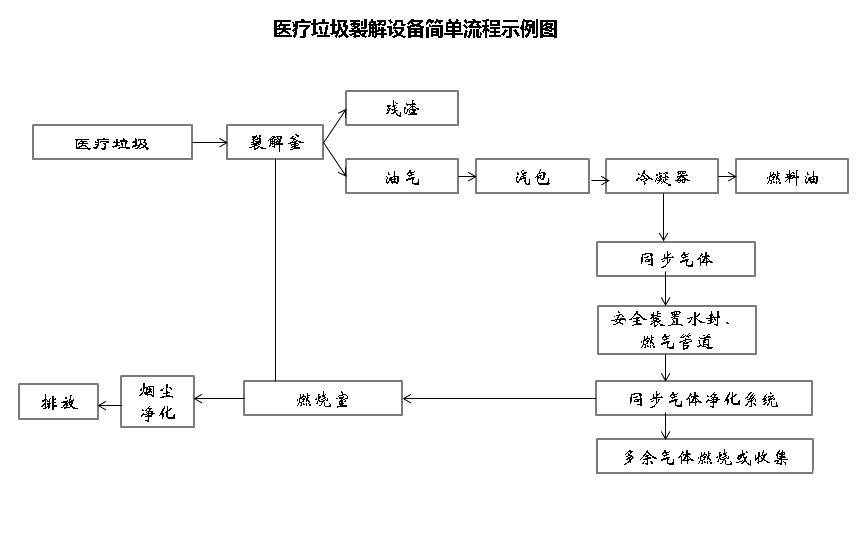

This comprehensive disposal process adopts high-temperature pyrolysis to dispose wastes. In the whole process, we don’t use any chemical additives which may produce toxic and harmful wastes. Exhaust air and tail gas can be recycled and disposed comprehensively by advanced equipment. There is no complex procedure in the process. The whole process happens in a closed high-temperature pyrolysis furnace. The simple operation produces no pollution to environment.

3. Efficient disposal and good effect

With efficient disposal, this system can meet Log8 standard.

4. Automatic disposal process

This system adopts advanced PLC control technology to realize automatic control. It mainly consists of: vacumm preheat control; heating, cooling, self start and stop control; adjustment control to time and temperature in cycle processing engineering; sterilization control of raffinate and waste cold water. This system holds advantages of convenient components, simple operation, safety and effectiveness.

5. Maximization of resource of utilization

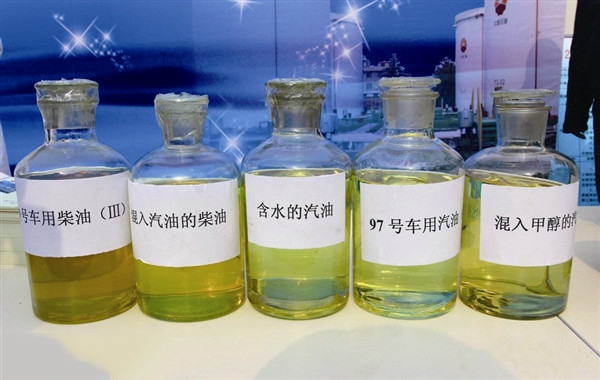

This system can efficiently make the disposal of medical garbages meet relavant standards. Garbage resouces can be recycled and utilized by this disposal process. Fuel oil, me

tals and other resources can be got while achieving disposal effect.

6. Lower running costs

The disposal developed by taida is easier. It needs no complex disposal equipments. Both construction cost and running cost are cheap. In addition, this process can recyle and utilize resources. As a result, better economic effects can be achieved.

7. More obvious on volume and quantity reduction

This disposal process can effectively recycle and utilize resources for medical garbages while realizing safe disposal. After recycling and utilization, these garbages are transferred into fuel oil and metals, which gurantees the effective volume and quantity reduction of garbages.

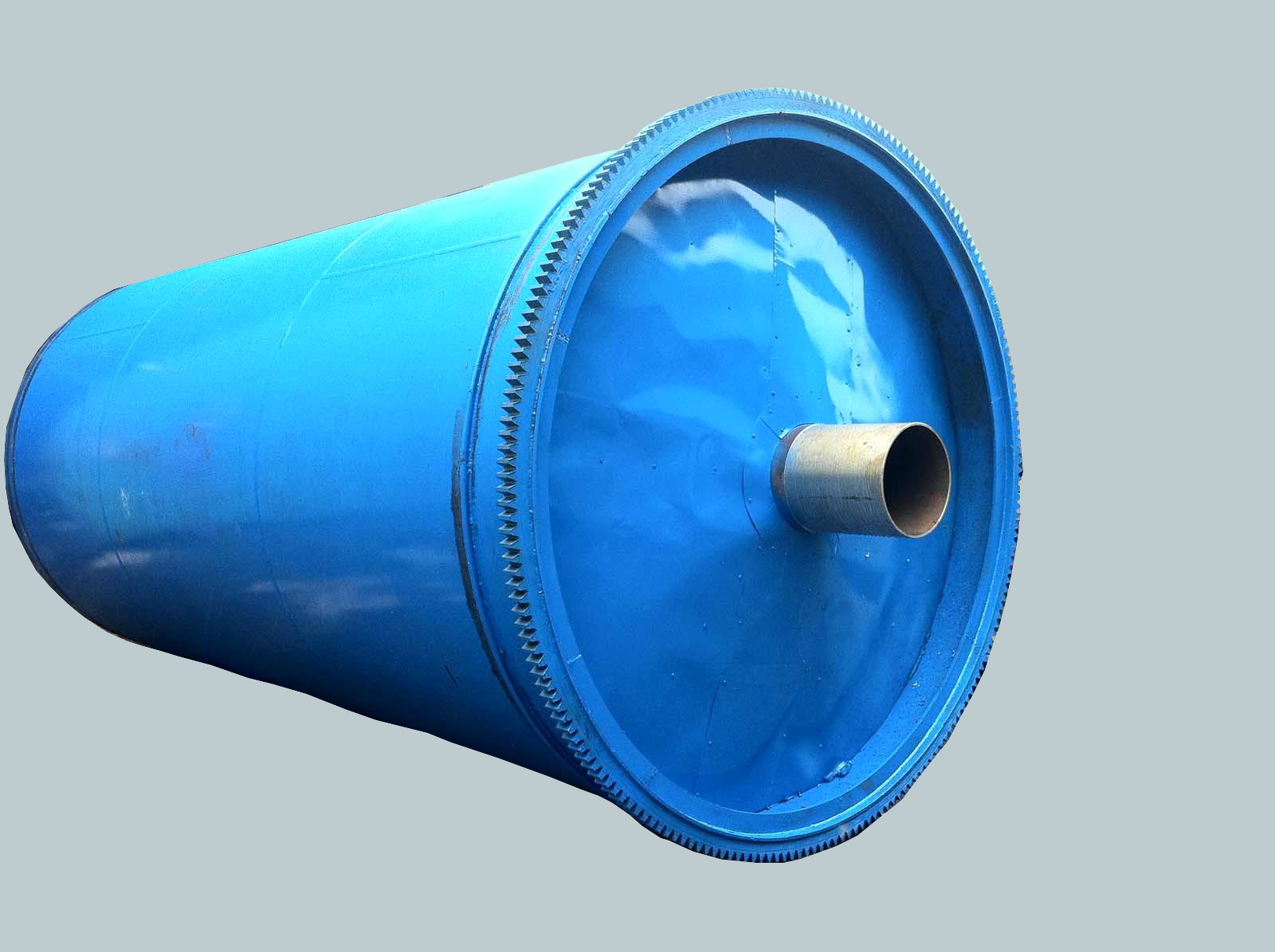

8. High-temperature pyrolysis system: it is a core product of taida. It is characterized by safety, enegy-saving, environmental protection and high ecnonomic effectiveness. It holds many inventions and patents. Products of taida have been sold to many provinces at home and many countries at abroad. This system mianly consists of feeder, high temperature cracking reaction kettle for medical garbages, slag tapping machine, condensating system, fuel receiving system, tail gas disposal system, electricity control system and waste material disposal system.

9. Tail gas purification system: it is mainly composed of efficient spray dust collection tower and other core systems. It holds many advantages such as high efficiency, low cost, convenient management and less maintenance.

10. Waste slag disposal system: this disposal process holds advantages of advanced technology, perfect slag collection and harmless disposal. It can dispose slags efficiently and produces no secondary pollution.

11. Instrument and automation control system: the medical garbages disposal system of taida adopts PLC control technology and precise instruments to finish automatic control of the whole process and precise monitoring.

12. Emergency handling, safety explosion-proof system: the medical garbages disposal system of taida takes advantages of many vedios to supervise pressure and temperature of key systems. This system can alarm automatically and effectively dispose abnormal situations, which makes the whole production process reliable.

中文

中文 English

English Home

Home