Technical introduction

In iron and metal industries, iron oxide should be cleaned out first by hydrochloric acid. In the process, a great amount of waste acid liquor will be produced. The acid liquor is mainly composed of free acid, ferrous chloride and water. the content of these compositions will be different according to different process, operating temperature, steel type and specifications. Generally speaking, the content of ferrous chloride is 20% to 26%. The content of free acid is 5% to 8%. The rest part is water.

There is large amount of this kind of waste liquor in our country. Generally, one-ton steel can produce 55 to 72 -kg waste acid. At present, steel and iron industry had become a giant source of water consumption and waste acid production. According to relevant statistics, iron and steel industry can produce more than 30-cubic-meter waste water. Aiming at this kind of water water, there are main two methods, namely Acid-base neutralization and Hydrochloric acid regeneration.

Sludge dryer can dry sludge, which provides convenience for the production of organic fertilizer. It is the best choice for enterprises which produces organic fertilizer. Sludge dehydration can make sludge used for agriculture and fuels, even makes the reduction of landfill land possible. Sludge dryer can be widely applied to drying active sludge, sewage sludge, petrochemical sludge, paper-making sludge, dyeing sludge, leather sludge, electrostatics sludge, municipal sludge and biological slags.

Advantages

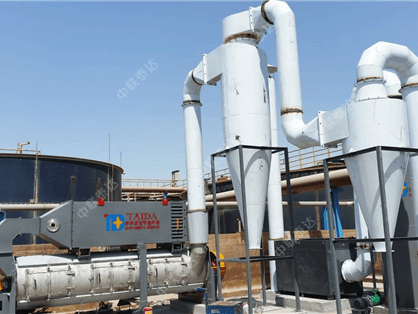

Petrochemical sludge dryer is mainly composed of induced draft fan, breaking-up device, belt loader, feeder, rotary drum, heat source, belt discharger, dumper and electricity distribution cabinet. Therefore, the work sections of sludge dryer consist of discharging section, lift plate section, cleaning section and materials leading section.

1. Conducting zone: wet sludge enters this section. Then, sludge will be evaporated quickly after contacting with hot wind. Under the function of big chamfer, materials will be led to next section before forming sticky materials.

2. Discharging section: there is not copy plate set in this section. Materials will slide to discharge port and finish the whole drying process.

3. Cleaning section: wet sludge will be lifted by copy plate and form material curtain. When materials fall, they easily stick on the rotary drum. Cleaning device set in this section can easily clean materials which stick on the drum. In this process, cleaning device can also crush materials cakes, which makes heating area larger and improves drying efficiency.

4. Inclined lifting plate section: wet sludge in this section presents a low-water and loose state. In this section, materials are not sticky. After heat exchange, the moisture content will meet demanded standard and enter final discharging zone.

Working principle

This dryer can dry sludge with 90% moisture content to dry final products. Aiming at the clumping feature of sludge, we change the structure of material plates. We adopt combined automatic cleaning device, which greatly expands the application of this dryer. It can not only dry various sludge, but also can dry various highly vicious materials.

sludge is sent to material conducting plate by feeder through chute. With the rotation of drum, sludge is led to inclined lifting plate and led to central place of drum. Then, materials are spread gradually and form a material curtain through which hot airflow pass. Sludge get preheated and partial moisture content is evaporated. When sludge is spread and moves to grate style wing, materials will mix with preheated grated style wing. Heat will be transferred to materials and partial moisture will be evaporated. Meanwhile, wing plate will lift and spread repeatedly. Materials will exchange heat with hot airflow. At the same time, cleaning device set in materials will slide along circular lifting plate and clean materials which stick on inner wall. When cleaning device rotate out vertical line and drag at the back side. Then, materials stick on outer wall of lifting plate will be eliminated. With continuous rotation of rotary drum, partial moisture content is evaporated and sludge will be further dried. Meanwhile, cleaning device also can crush materials cakes. Drying speed will be increased. After drying, materials will become low-water and loose materials and discharged out from discharging port.

Technical parameters

|

Model |

Drum Diameter (mm) |

Drum Length (mm) |

Drum Volume(m3) |

Rotary Speed (r/min) |

Power (kW) |

Weight (t) |

|

HG0.6×6 |

600 |

6000 |

1.7 |

1-8 |

3 |

2.9 |

|

HG0.8×8 |

800 |

8000 |

4 |

1-8 |

4 |

3.5 |

|

HG1×10 |

1000 |

10000 |

7.9 |

1-8 |

5.5 |

6.4 |

|

HG1.2×6 |

1200 |

6000 |

6.8 |

1-6 |

5.5 |

6.7 |

|

HG1.2×8 |

1200 |

8000 |

9 |

1-6 |

5.5 |

8.5 |

|

HG1.2×10 |

1200 |

10000 |

11.3 |

1-6 |

7.5 |

10.7 |

|

HG1.2×12 |

1200 |

12000 |

13.6 |

1-6 |

7.5 |

12.5 |

|

HG1.5×8 |

1500 |

8000 |

14.1 |

1-5 |

11 |

14.8 |

|

HG1.5×10 |

1500 |

10000 |

17.7 |

1-5 |

11 |

16 |

|

HG1.5×12 |

1500 |

12000 |

21.2 |

1-5 |

15 |

17.8 |

|

HG1.5×15 |

1500 |

15000 |

26.5 |

1-5 |

15 |

19.2 |

|

HG1.8×10 |

1800 |

10000 |

25.5 |

1-5 |

15 |

18.1 |

|

HG1.8×12 |

1800 |

12000 |

30.6 |

1-5 |

18.5 |

21 |

|

HG1.8×15 |

1800 |

15000 |

38.2 |

1-5 |

18.5 |

26.3 |

|

HG1.8×18 |

1800 |

18000 |

45.8 |

1-5 |

22 |

31.2 |

|

HG2.2×12 |

2200 |

12000 |

45.6 |

1-4 |

22 |

31 |

|

HG2.2×15 |

2200 |

15000 |

53.2 |

1-4 |

30 |

36.2 |

|

HG2.2×18 |

2200 |

18000 |

68.4 |

1-4 |

30 |

43.3 |

|

HG2.2×20 |

2200 |

20000 |

76 |

1-4 |

30 |

48.8 |

|

HG2.4×15 |

2400 |

15000 |

67.9 |

1-4 |

30 |

43.7 |

|

HG2.4×18 |

2400 |

18000 |

81.4 |

1-4 |

37 |

53 |

|

HG2.4×20 |

2400 |

20000 |

90.5 |

1-4 |

37 |

60.5 |

|

HG2.4×24 |

2400 |

24000 |

108.6 |

1-4 |

45 |

69.8 |

|

HG2.8×18 |

2800 |

18000 |

110.8 |

1-4 |

45 |

71.6 |

|

HG2.8×20 |

2800 |

20000 |

123.2 |

1-3 |

55 |

76.8 |

|

HG2.8×24 |

2800 |

24000 |

147.8 |

1-3 |

55 |

85 |

|

HG2.8×28 |

2800 |

28000 |

172.4 |

1-3 |

75 |

95 |

|

HG3×20 |

3000 |

20000 |

141.4 |

1-3 |

55 |

87 |

|

HG3×24 |

3000 |

24000 |

169.7 |

1-3 |

75 |

105 |

|

HG3×28 |

3000 |

28000 |

198 |

1-3 |

90 |

123 |

|

HG3.2×24 |

3200 |

24000 |

193 |

1-3 |

90 |

120 |

|

HG3.2×28 |

3200 |

28000 |

225.2 |

1-3 |

90 |

140 |

中文

中文 English

English Home

Home