Taeda E-style C-type Rotary Wing Dryer makes up the technical gap in drying machine which can integrates drying and crushing into a whole. This new type dryer can be used to dry materials with 95% moisture content. It can be also used to dry materials with less moisture content without special feeding condition. Air velocity and material’s retention time are changeable. Also, materials suitable for being dried by this kind of dryer is not singular. With wide application fields, it can be used to dry granular materials and power materials. According to discharged temperature and material’s size, residual moisture of final products differ, from 1% to 10%.

This series of equipment can be used to dry wide range and various type of materials such as Aluminum hydroxide, bentonite, bone meal, liquor, calcium carbonate, cellulose, ceramic fiber, grain, animal waste, fruit residue, animal protein, municipal waste, various sludge and etc.

After drying process, sludge can be used as gardening soil, planting soil, foundation soil and cohesive soil in cement industry, which can effectively realize harmless reutilization of sludge and achieve energy-saving and circular economy aim. Secondary pollution can be completely avoided.

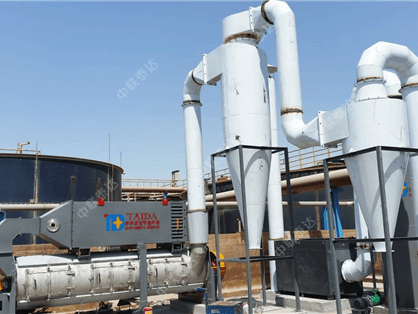

E-style OSC Rotary Wing Dryer is Taeda fifth generation technical innovation, with super less occupation area, low energy consumption and good drying effect.

Now share a table comparing multiple sludge drying equipment:

|

No. |

Equipment name |

Output |

Power |

Electricity |

Coal consumption |

Labor force |

Occupation area |

|

1 |

First generation traditional rotary dryer |

1t/h |

37kw |

25.9° |

400-500kg |

5 |

260㎡ |

|

2 |

Second generation sludge rotary dryer |

1t/h |

30kw |

21° |

300-400kg |

4 |

230㎡ |

|

3 |

Third TDOSA European style dryer |

1t/h |

22kw |

15.4° |

200-350kg |

4 |

180㎡ |

|

4 |

Fourth generation Double-shaft hot air mixing dryer |

1t/h |

18.5kw |

13° |

200-300kg |

3 |

140㎡ |

|

5 |

Fifth generation TDOSC air swept rotary wing dryer |

1t/h |

15kw |

11° |

100-250kg |

2 |

90㎡ |

Features of new type OSC dryer:

◎This dryer holds wide application range, can be applied to deal with materials which cannot be dealt with by common dryer.

◎Whole drying system holds strong controllability. Can be matched with various fuels, like natural gas, oil, or oil. Discharging system is controlled by temperature instrument in discharging tube.

◎This drying system adopts advanced drying technology in international world, with good drying effect.

◎Can be used to deal with wide range of raw materials, from low-solid slurry to low-moisture powder, can be used to deal with almost any kinds of raw materials.

◎Raw materials’ routine in dryer can be controlled, final products’ state can be flexibly adjusted.

◎This dryer can use coal, electricity, oil, natural gas as heat source. Drying hot air can be classified into primary hot air and secondary hot air.

◎ Equipment disposal capacity is in a wide range, from 100kg to several tons.

◎Working efficiency is 70% to 90% (will be different if heat mode is not same).

◎Production process is environment friendly, final products holds uniform particle, with less occupation area, final products hold high quality.

◎With reasonable equipment structure, low occupation area, low noise, low vibration. Adopt reliable PLC control. Matched with efficient and clean combustion furnace and tail gas purification system, can achieve efficient, low energy-consumption and zero pollution aim.

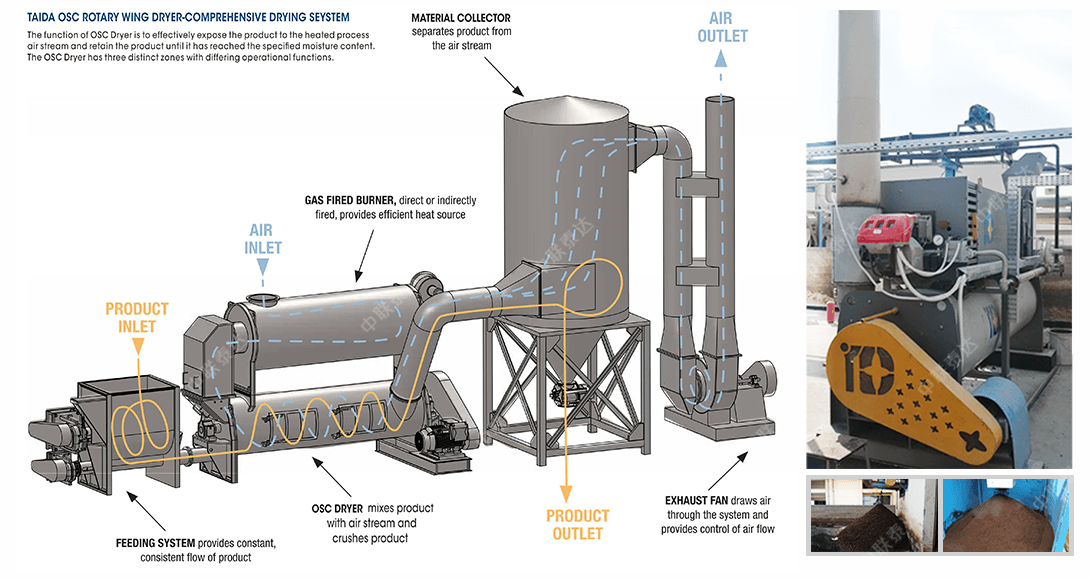

E-style OSC Rotary Wing Dryer(also called AST dryer) adopts the most advanced drying technology. It can almost deal with any kinds of materials, from low-solid contents to low-moisture powder. Materials’ routine in dryer can be easily controlled. Therefore, this drying system can be used to produce dry fine powder and moist granular materials. There are three separate zones set in the drying system. Central retention zone decides the residual moisture and physical size of final products. Although this drying system adopts high temperature difference, but same with majority instant dryers, products’ temperature is lower than wet ball humidity. Heat source of this dryer can adopt oil-fired or gas-fired hot air fan. Generally speaking, heat source device is always integrated with drying cylinder. Products can enter terminal region directly from drying tubes. Final products can be collected by separator and bag filter. This series of dryer contains 9 sizes. Evaporation speed can reach as high as 8ton per hour.

From the mechanical structure of the equipment.Taeda AST rotary wing drying crushing machine is a new innovative drying equipment developed by Taeda based on absorbing foreign advanced technology. It combines advantages of rotary drum rotary wing dryer (E-style dryer), airflow dryer and paddle dryer. Air swept dryer is especially suitable for drying task of low solid and liquid state materials, like sludge, spent grain, desulfurized gypsum, alumina hydroxide filter cake, plasma and other similar materials.

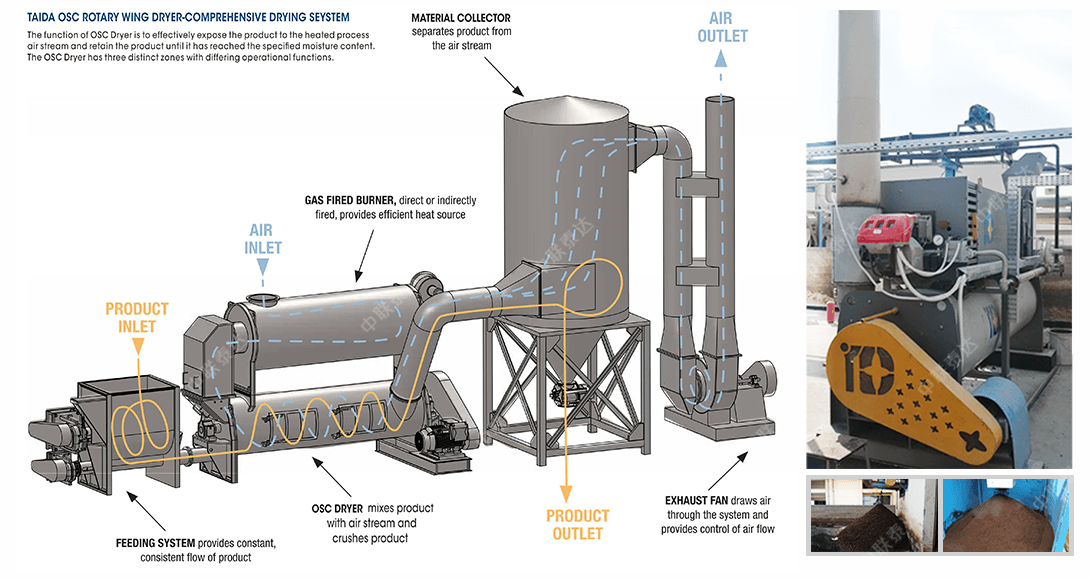

Drying medium (hot air) enters dryer through air inlet. Materials are fed to dryer through feeding inlet by screw feeding unit. Wet materials will be dispersed and stirred by air swept device inside drum. Moisture will be evaporated fast after fully contacting with hot air. Under the function of air flow force, wet materials enter second stage where residence time is extended under the function of material-backing device and damper. Meanwhile, dried materials at rear part will fully mix with material at front part. Materials present suspension state. Owing to mixing, stirring and crushing function, heat exchanging effect can be done sufficiently. Dried materials will be discharged out together with hot air from discharging outlet and drying process is finished. Please refer to following chart for work process.

■Mixing, crushing, granulating and drying process are finished in one machine under granule production mode. Wet materials can be dried into dry powder one time under super-dry powder production mode and final moisture is lower than 5%.

■High thermal efficiency; under the function of rotary wing shaft, materials present boiling suspension state, which makes wet materials fully contact with hot air. Thermal efficiency is higher than common dryer.

■Advanced technology, low noise and high automation level. It adopts international advanced technology and we have good command of core technology and running parameters.

|

Item |

TDOSC310 |

TDOSC510 |

TDOSC1010 |

TDOSC2010 |

TDOSC3010 |

TDOSC4010 |

TDOSC5010 |

|

Thermal value(10^4kCal/h) |

10 |

15 |

30 |

65 |

130 |

180 |

250 |

|

Hot air(m3/h) |

2500 |

3720 |

7500 |

16000 |

32000 |

45000 |

70000 |

|

Max evaporation(kg/h H2O) |

360 |

550 |

1100 |

2200 |

4500 |

5500 |

7800 |

|

Power(kW) |

7.5 |

11 |

30 |

55 |

75 |

110 |

160 |

|

L(mm) |

3800 |

4080 |

5200 |

5500 |

6500 |

10500 |

12000 |

|

W(mm) |

1200 |

1500 |

2200 |

2900 |

3200 |

3800 |

4580 |

|

H(mm) |

835 |

1000 |

1390 |

1800 |

2200 |

2680 |

3320 |

中文

中文 English

English Home

Home