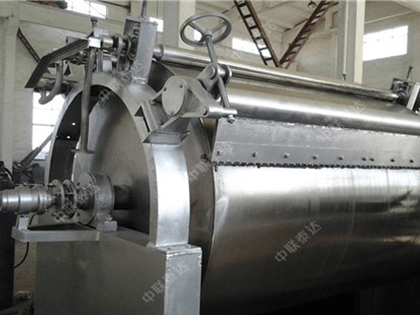

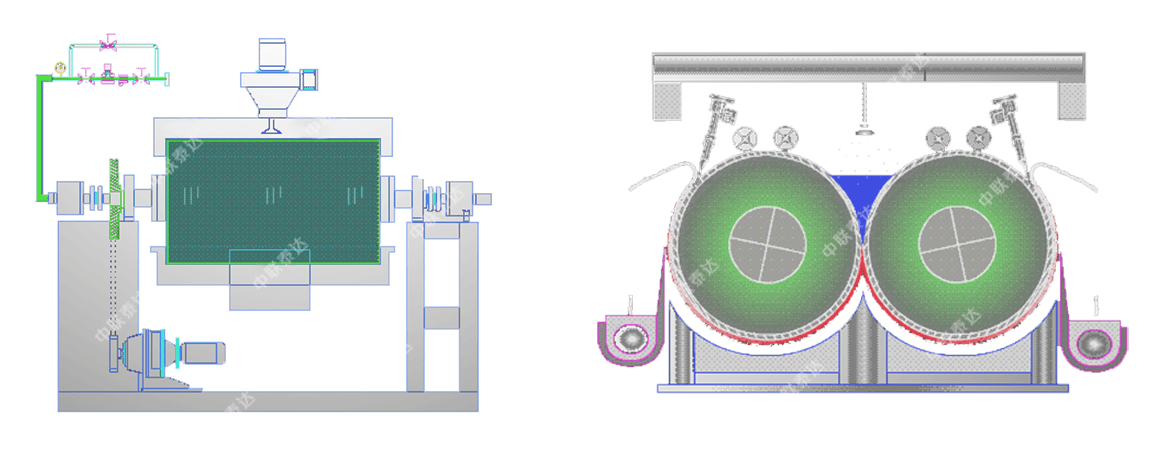

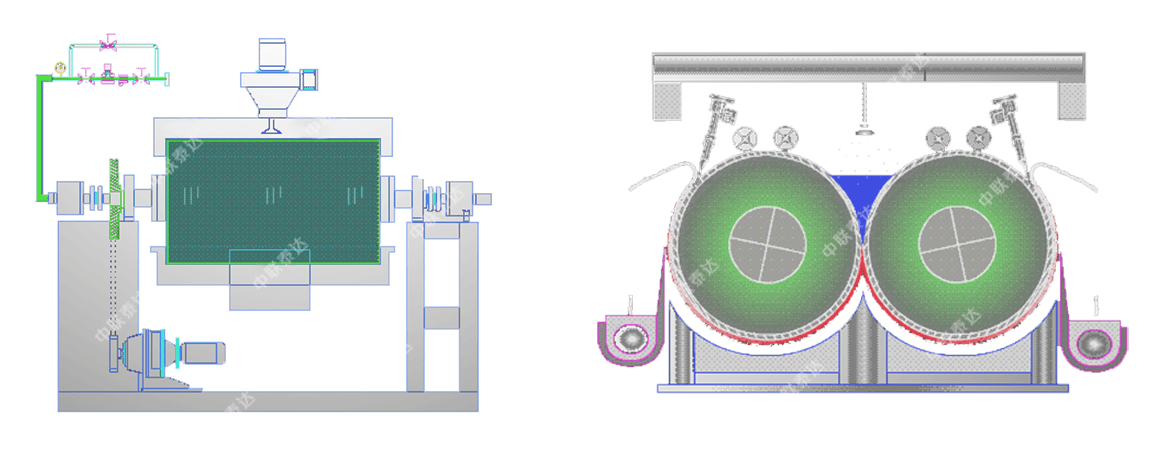

Taeda GERG rotary drum scrapper dryer is a kind of continuous drying equipment which adopts internal heating conduction. Rotary drum passes through its lower sliding chute and rotary drum is carried out materials with certain thickness. Heat is transferred to internal drum wall through pipe and conduced to external drum wall. Then, heat will be transferred to material film for moisture evaporation and dehydration. Wet materials can be dried. Dried materials will be scrapped out of drum by scrapper installed on drum. Screw conveyor set under scrapper will send materials for centralized packaging. GERG dryer is especially suitable for drying paste slurry materials with certain stickiness. Typical material for GERG dryer is yeast. GERG dryer can not only solve the difficulty that yeast is not resistant high temperature, but also can effectively and continuously dry wet sticky yeast.

◎High thermal efficiency

Because rotary drum dryer heat transfer is a kind of heat conduction, heat transfer direction keeps same during whole operation period. Except heat radiation and dissipation loss, all other heat can be used for evaporation of moisture in material film. Thermal efficiency can reach 70% to 80%.

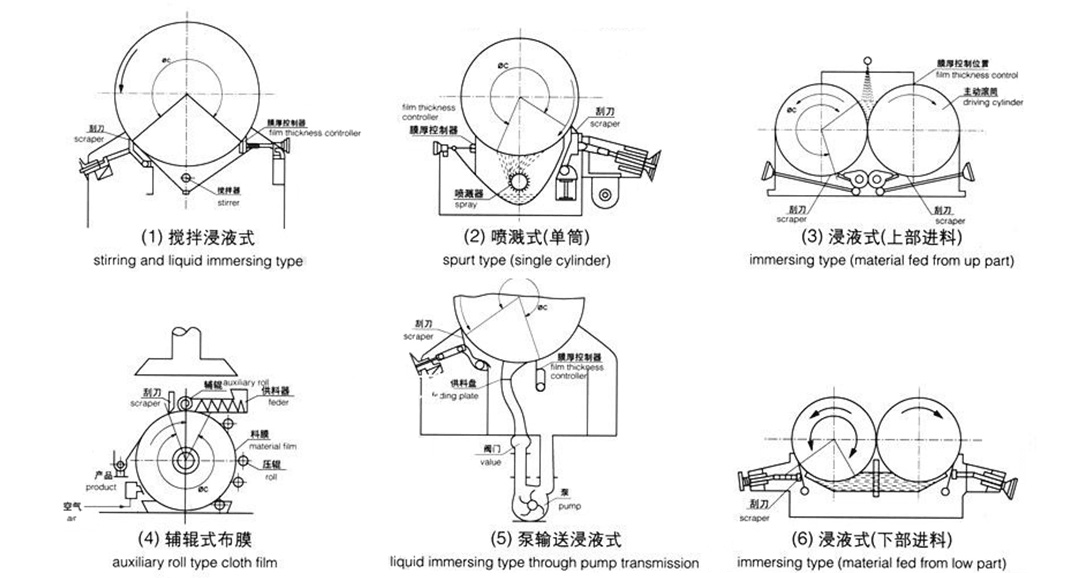

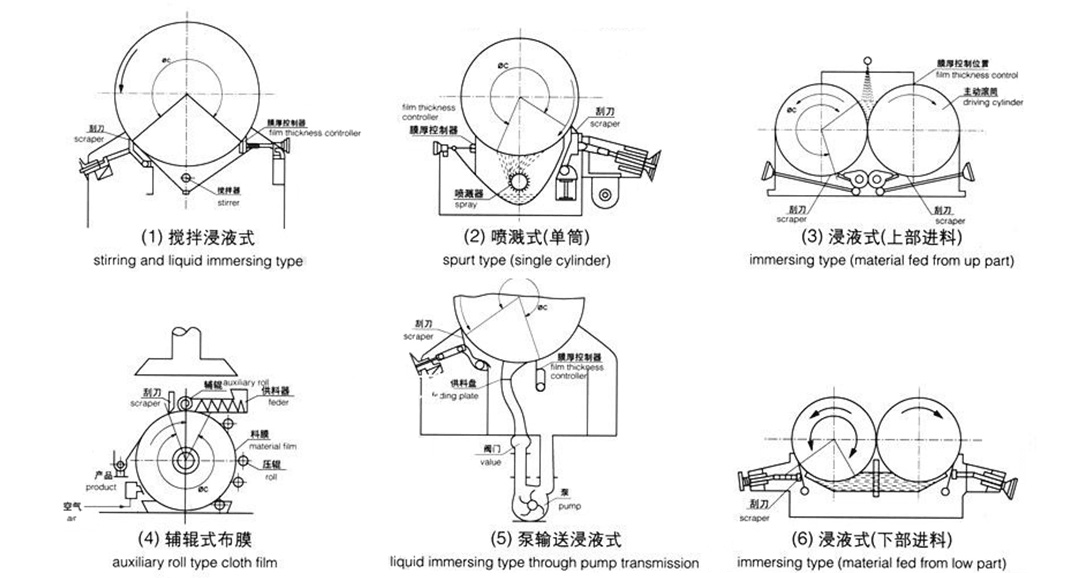

◎Flexible operation and wide application

Multiple drying elements of drum dryer can be adjusted, like feeing concentration , film thickness, temperature of heating medium and drum rotation speed so that to change drying efficiency. Each element has no impact on each other, which provides great convenience for operation of the dryer. It can meet drying demands and capacity requirements of various materials and

◎Short drying period

Generally, drying period is only about 10-300 seconds. Suitable for drying heat-sensitive materials.

◎Strong drying ability

Because the material film coated on drum is not thick, only about 0.3-1.5mm, heat and mass transfer direction are same. Evaporation capacity of material film can be kept between 20-70kg.H2O/m2.h.

Taeda GERG rotary drum scrapper dryer is a kind of continuous drying equipment which adopts internal heating conduction. Rotary drum passes through its lower sliding chute and rotary drum is carried out materials with certain thickness. Heat is transferred to internal drum wall through pipe and conduced to external drum wall. Then, heat will be transferred to material film for moisture evaporation and dehydration. Wet materials can be dried. Dried materials will be scrapped out of drum by scrapper installed on drum. Screw conveyor set under scrapper will send materials for centralized packaging.

|

Specifications |

Size of rotary drum |

Effective heating area (m2) |

Drying capacity

kg.H2O/m2.h |

Steam consumption

(kg/h) |

Power(kw) |

Overall size(mm) |

Weight(kg) |

|

HG-600 |

Φ600×800 |

1.12 |

40-70 |

100-175 |

2.2 |

1700×800×1500 |

850 |

|

HG-700 |

Φ700×1000 |

1.65 |

60-90 |

150-225 |

3 |

2100×1000×1800 |

1210 |

|

HG-800 |

Φ800×1200 |

2.26 |

90-130 |

225-325 |

4 |

2500×1100×1980 |

1700 |

|

HG-1000 |

Φ1000×1400 |

3.30 |

130-190 |

325-475 |

5.5 |

2700×1300×2250 |

2100 |

|

HG-1200 |

Φ1200×1500 |

4.24 |

160-250 |

400-625 |

7.5 |

2800×1500×2450 |

2650 |

|

HG-1400 |

Φ1400×1600 |

5.28 |

210-310 |

525-775 |

11 |

3150×1700×2800 |

3220 |

|

HG-1600 |

Φ1600×1800 |

6.79 |

270-400 |

675-1000 |

11 |

3350×1900×3150 |

4350 |

|

HG-1800 |

Φ1800×2000 |

8.48 |

330-500 |

825-1250 |

15 |

3600×2050×3500 |

5100 |

|

HG-1800A |

Φ1800×2500 |

10.60 |

420-630 |

1050-1575 |

18.5 |

4100×2050×3500 |

6150 |

中文

中文 English

English Home

Home