Technical introduction

Sludge incineration is one of sludge disposal processes It heat and dry dewatered sludge by using incineration furnace. Then, change sludge into small amount of ash by making use of organic matters in high-temperature oxidized sludge. Incineration is a kind of amount reduction, stablization and harmless disposal method for sludge. It can completely eliminate organic matters in sludge and kill pathogen. Taeda sludge solid wastes incineration system can be applied for large-medium sized developed cities, large wastewater treatment plants in large towns and urban sewage treatment plants with high content toxic matters.

Five major system devices

1、Automatic control device

Adopt Siemens PLC, Taeda electrical department specially designs complete automatic control program for sludge incineration system.

2、Exhaust gas purification device

Cyclone dust collector, condensing cooling, water scrubbing, comprehensive cleaning device. Taeda customized deodorization system effectively reduces odors in workshop.

3、Incineration device

Taeda have been specialized in drying industry for more than 60 years. Specially designed furnace hearth structure integrates pyrolysis, incineration and deodorization into a whole. Whole system is equipped with multi-layer shielding, frequency-conversion transmission and combustiable support wind supplying device with adjustable rotary angle.

4、Conveying device

There are various conveyors available for choice like sludge pressing conveyor, screw pump, plunger pump, screw conveyor, belt conveyor, scrapper conveyor and bucket elevator. It should be decided according to facts.

5、Drying device

Rotary drum sludge drying system, with compact process structure, less occupation area, wide application range, reliable performance, simple operation and high safety level.

Advantages

Taeda sludge harmless incinerating system is a pretty good solution. This system can greatly reduce acide matters (SOX and HCL) content in flue gas through grading combustion and adding alkaline matter. This system is characterized by large input capacity, large scale, long service life and low running cost. It has been widely applied at home and abroad. It is also a mainstream technology highly recommended.

Working principle

Key procedure of sludge drying incinerating system is to reduce sludge moisture. Sludge thermal drying process is a pretty good method to reduce sludge moisture. There have already been lots of practical examples in Jan, Europe and other countries. Major equipments have been applied for engineering project. Incineration system mainly consists of following operation units: sludge conveying system, sludge drying system, incineration furnace, exhaust heat steam boiler, flue gas disposal system, ash collecting and conveying system.

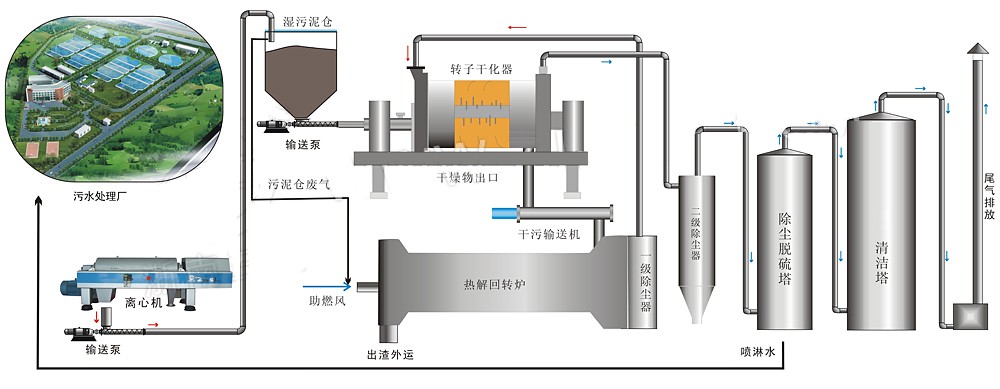

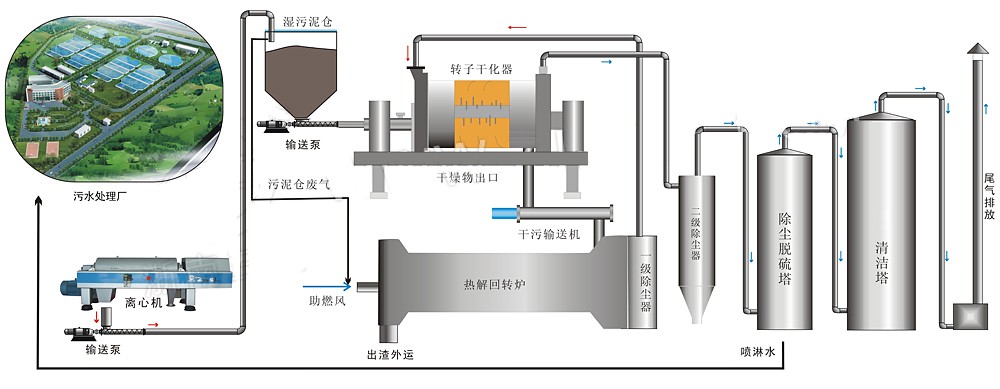

Taeda sludge incinerating process procedures

Wet sludge will be sent to wet sludge silo by truck. ID fan equipped can send odor produced by sludge to exhaust gas purification device. Wet sludge is sent to the rotary drum dryer. Wet sludge is driven forward by the rotation of rotary shaft. Heating and drying purpose is realized in dryer. Dried sludge is transferred to incineration system by sludge cooler. Exhaust gas after sludge drying contains large amount of vapor. After condensing, dewatered exhaust gas is led to exhaust gas purification device. Evaporation amount of single drum dryer is 830 to 6700kg/h. Maximum input capacity of single machine is 25 to 200t/day for sludge with 80% moisture.

Taeda sludge Incinerating system composition:

A. Sludge feed machine: sludge is sent to incinerator consistently, uniformly and stably.

B. Incinerator: it is used to incinerate partially dried sludge so that to meet requirements of sludge disposal; include ignition and standby firing system.

C. Combustion air system: include primary air, secondary air; whether secondary air is set or not is decided according to process characteristics.

D. Deslag and sand adding system: these system discharge furnace slag discontinuously. Then cooling, screening, conveying and storing furnace slag; due to the tapping slag of incinerator, furnace charge is reduced. As a result, materials and sand should be added.

E. Thermal insulation system: it is used to heat preservation of relevant equipment and systems.

F. Auxiliary system:It can be applied to switch on, stop, start up and run equipment in any situations (normal or abnormal).

G. Equipment supports; maintenance platform and stairs; all pipelines and supports, valves, dashboard, couplings, foundation bolts, binding bolts, cables and crane span structure.

H. Electric accessories: (if working temperature of electricity distribution system can’t be guaranteed after adopting forced ventilation and heat thermal insulation measures), electricity distribution cabinet and control cabinet with air conditioner should be provided.

Technical parameters

|

Input capacity |

Power/kw |

Occupation area/m2 |

Notes |

|

Running power |

Installed power |

Core equipment |

Whole system |

|

10t/d |

17.5 |

30 |

20 |

90-125 |

Provide comprehensive technical support. |

|

20t/d |

22.5 |

40 |

24 |

125-175 |

|

50t/d |

30 |

50 |

32 |

175-300 |

|

100t/d |

45 |

70 |

48 |

300-400 |

|

150t/d |

55 |

90 |

60 |

350-450 |

Taeda Company Drying Test Center

At present, our company has set test center: WGF005/A-I-001 model(daily input 5t for 80% moisture sludge)sludge drying-incinerating device.

Please contact us if you have relevant demands. Email: service@tdaxy.com wechat/whatsapp:+86 18539990967.

中文

中文 English

English Home

Home