TDHP heat pump drying system (low temperature drying line) adopts low temperature condensation and dehumidification technology. Sludge with 65% to 80% moisture is transported to top of dryer through a spiral lifting device. Then through pelletizing or extruding machine, sludge will be granulated or extruded according to features. Extruded/granulated sludge will fall to the mesh belt conveyor line. Hot air is input from the bottom of the line (air temperature supplied is 75 degrees) to directly dry the sludge. Hot air with evaporated water of sludge is recycled from the top (returning air temperature is 45 degrees). Moisture is collected and discharged through condensation and dehumidification. At this moment, hot air with lower water saturation is heated to 75 degrees by heating device and sent back to bottom of the production line for continuous circulation and achieve sludge drying aim. Mesh belt production line adopts frequency conversion stepless speed regulation. Dryness of the sludge can be adjustable from 10% to 60%.

Characteristics of heat pump sludge drying system (low-temperature sludge drying line): before sludge drying machine, sludge is pelletized/granulated or extruded first, which increases contact surface area between sludge and hot air and drying efficiency is greatly improved. Dried sludge remains in the form of particles or strips. There is no dust generated. Because the low-temperature drying process, organic matter in sludge is not destroyed and heat value for later incineration is higher. Adopt closed condensation dehumidification method, no odor leakage and no pollution to the environment. Dryness of sludge can be adjusted according to demand and no energy will be wasted due to excessive drying. Whole is easy to install and does not require complicated civil construction investment. Because it does not produce any pollution discharge, it can be used in cities and industrial parks.

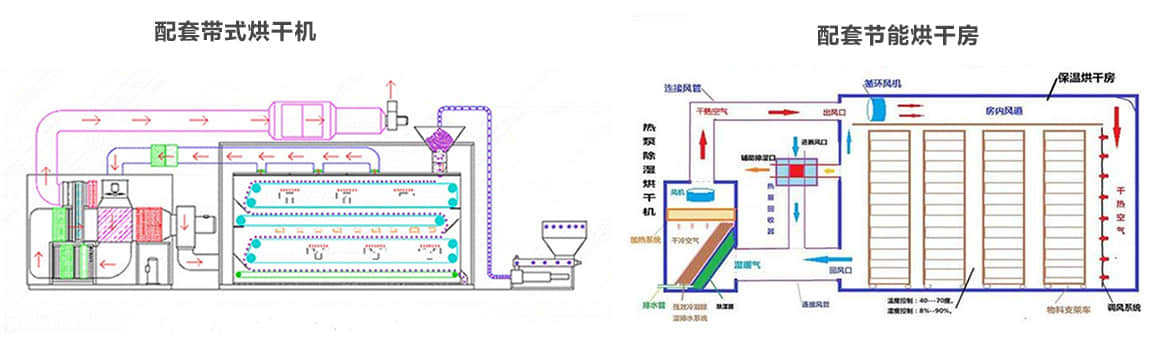

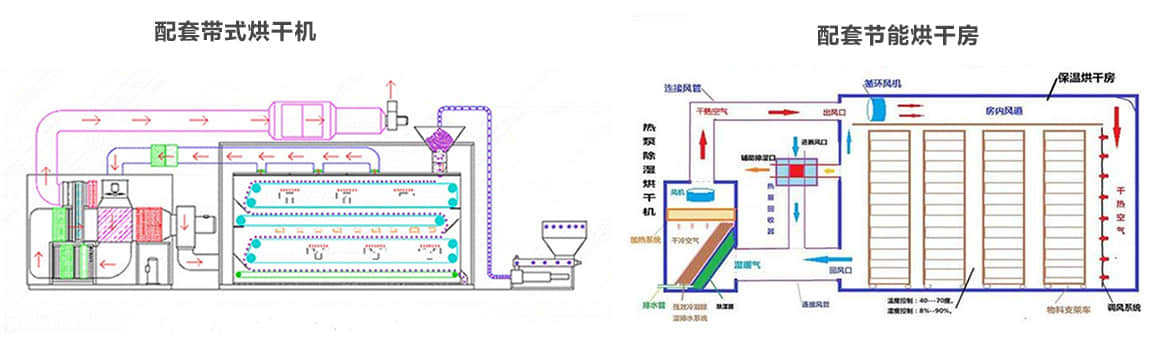

TAEDA heat pump drying system holds wide application range. Dehumidification heat pump drying makes use of a refrigeration system to cool and dehumidify moist air from drying chamber. Meanwhile, while recover moisture, condensate latent heat and heat air through principle of heat pump to achieve the purpose of drying materials. Dehumidification heat pump is a combination of dehumidification (dehumidification and drying) and heat pump (energy recovery) to make energy recycling during the drying process. Air circulation mode and air dehumidification mode of dehumidification heat pump drying are different. During drying process, air presents a closed cycle between drying chamber and dehumidification dryer (no exhaust heat discharged). Traditional hot air drying is kind of dry type system which makes use of fuel to heat air and discharges air after absorbing moisture absorption (discharge exhaust heat). Energy utilization efficiency is low (20%-50%). For drying sludge materials, heat pump dryer is always used in conjunction with drying room and the mesh belt dryer of our company and drying effect is remarkable. Following figure shows the process chart of these two drying methods.

|

Model |

TDHP5000 |

TDHP10000 |

TDHP15000 |

TDHP20000 |

TDHP25000 |

|

Evaporation capacity/24h |

~5000kg |

~10000kg |

~15000kg |

~20000kg |

~25000kg |

|

Running power |

13Kw |

26Kw |

39Kw |

52Kw |

65Kw |

|

Thermal power |

200Kw |

400Kw |

600Kw |

800Kw |

1000Kw |

|

Power supply |

380V/3H/50HZ |

|

Standard drying temperature |

50~65℃(Return air)/68-85℃(Blow air) |

|

Final moisture |

frequency conversion adjustment, initial moisture (10% to 60%), it all depends feeding moisture content. |

|

Overall dimensions (mm) |

4560*3110*3200 |

7900*3110*3200 |

11150*3110*3200 |

14400*3110*3200 |

17650*3110*3200 |

|

Weight |

5.7t |

8.6t |

12.3t |

14.8t |

16.5t |

中文

中文 English

English Home

Home