Oil sludge is accompanying product and major pollution source produced in petroleum production. Oil sludge is a difficult problem which will affect surrounding oil field and environment. In addition, oil sludge contains large amount of organic matters, rich nitrogen, phosphorus and sulpur which will cause great harm to environment and human beings.

Aimed at kind of solid wastes, Taeda designs and develops WSC series oil sludge disposal equipment. Whole purification process is scientific, reasonable, stable and reliable. Whole process and equipment are mature and high automatic which can help reduce disposal cost. Sludge with low oil content holds less value for recycling and disposal circle can be simplified, which not affect the harmless disposal and amount reduction will aim.

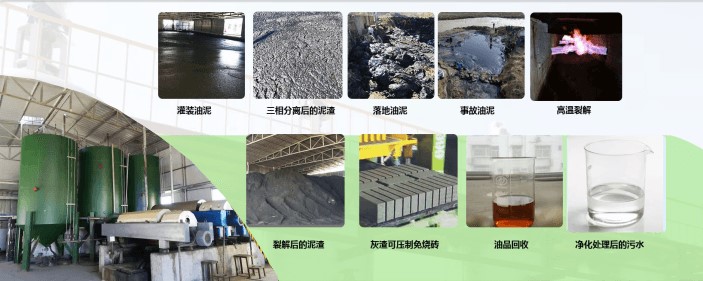

Comparison of oil sludge before and after drying and pyrolysis process:

Social profit and application prospect:

Taeda WSC series oil sludge disposal system can be used to treat great amount of oil sludge every year. It is a very effective method for oil sludge disposal and holds good social effect. It is a kind of advanced treatment method. It can avoid pollution caused to environment and pyrolysis produced can be reused as good resources.

WSC series equipment adopts environment friendly, energy-saving and harmless disposal method during oil sludge disposal process. There is no secondary emission and it holds good superiority and is regarded as a practical technology. It is featured in low investment, large capacity and quick effect. WSC series oil sludge disposal equipment has been sold to more than ten countries and regions. It is a disposal equipment with great market prospect.

中文

中文 English

English Home

Home