Technical introduction

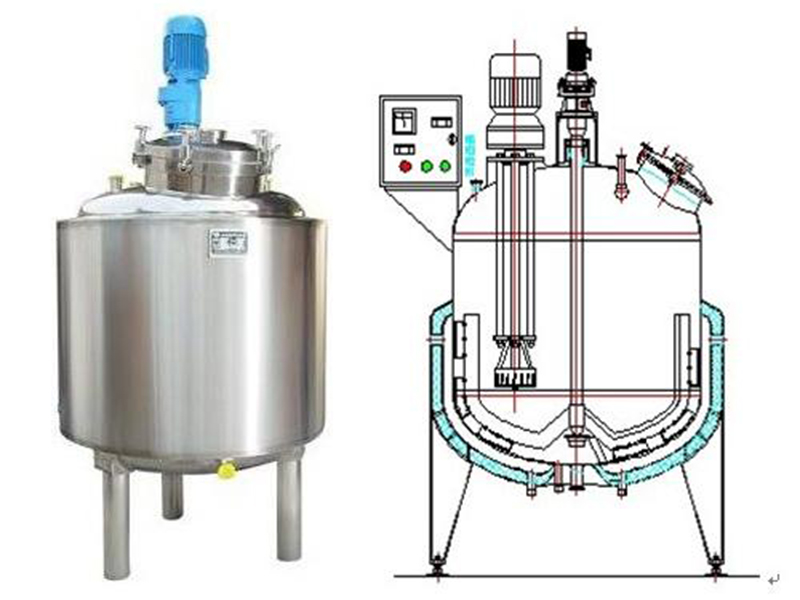

Stainless agitating/mixing tank profile:

Stainless-steel agitating tank can also be called aqueous phase tank. It is widely applied to coating, medicine, building materilas, chemistry, pigment, resin, food and scientific research. According to customer’s process requests, we choose different materials for equipment such as carbon steel and stainless steel and set proper heating and cooling device in order to meet different process and production demands. There are several kinds of heating forms such as jacket electrical heating and coil heating. This equipment holds many advantages such as reasonable design, advanced technology, durable service, simple operation and convenient use. It is an ideal equipment which needs less investment, quick production and high profits.

Advantages

Stainless-steel agitating tank is composed of agitating tank, agitating tank cover, agitator, supports, transmission device and shaft sealing instrucment. Heating device and cooling device can also be installed according to real requests.

It adopts flange sealing connection or welding link between stainless-steel tank and tank cover. According to technical requests, there can be feeder, dischargers, supervising, temperature messurement, pressure measurement, steam fractionation and safe vent devices installed.

On the cover of stainless-steel tank cover, there is one transmission device (motor or reducer). Agtitator in tank will be driven by transmission shaft.

Shaft sealing device can adopt mechanical seal, labyrinth seal and other forms (decided by customer’s demand ).

Agitator can adopt paddle type, anchor type, frame type and screw type.

Working principle

Application of heating or cooling device is decided by whether materials need heating or cooling. In the designed range, the temperature should controlled under 230 degree centigrade and working pressure should be controlled under 0.1 Mpa. Heating method is normally divided into two kinds, media circulating heating and direct electrial heating. Hot oil and other media circulating heating method: heat conduct oil are heated to a certain temperature in a another configurated machine. Conveying and circulating are finished in heat oil pump. Direct heating: electrial heating pipe is installed on jacket. Then, heat conduction oil is heated to a requested temperature (temperature can be adjusted according to real situations). Cooling circulating: water circulates in the inner and outer side of jacket, which makes it difficult for materias to produce agglomeration and stickness.

Technical parameters

The installation and degugging of stainless-steel agitating tank

1. Check if there is severe damage and deformation; check if there is anly

Loose phenomenon of the fastening pieces in equipment;

2. Adopt embedded anchor bolts; on the firm basic, install the equipment horizontally;

3. Under the guidance of professional persons, install equipment, electrical control and other accessories correctly; check whether the pipeline flows smoothly; check whether the installation of instrucments is right; check whether there is any damage; before starting the equipment, check if ther is person or things which would affect the normal operation of machine in order to avoid danger;

4. After finishing installation, carry out test run for seconds; after makin sure there is no electrical short circuit and strange noise, short-time test run can be carried out;

5. If there is mechanical seal set on agitating tank, before starting the host, pouring certain amout of 10# or sewing machine oil. Cooling water must be injected into cooling chamber in order to that mechanical device gets good lubrication and cooling. Mechanical seal hasn’t got adjusted while it leaves factory. After finishing installations, adjust the mechanical seal to best position according to instructions. Then, normal running can be carried out.

6. After the normal running of equipment, check the temperature of shaft, stabilities of running, leak tightness and the instruments; after making sure the normal running of equipment, start feeding;

中文

中文 English

English Home

Home