Papermaking sludge dryer is a kind of necessary equipment in modern society. However, papermaking industry causes too much sewage and sludge which brings severe pollution to environment. It is a challenge which EHS cause has to always face. Paper making sludge belongs to biological solid wastes which contain organic matters, plant nutrients, heavy metals and pathogenic. According to relavant national requirements, papermaking sludge should be recycled by qualified enterprises. After being disposed by papermaking sludge dryer, the weight of papermaking sludge and the cost of disposal will be greatly reduced.

Product description:

1. Papermaking sludge dryer is a kind of necessary equipment in modern society. However, papermaking industry causes too much sewage and sludge which brings severe pollution to environment. It is a challenge which EHS cause has to always face. Paper making sludge belongs to biological solid wastes which contain organic matters, plant nutrients, heavy metals and pathogenic. According to relavant national requirements, papermaking sludge should be recycled by qualified enterprises. After being disposed by papermaking sludge dryer, the weight of papermaking sludge and the cost of disposal will be greatly reduced.

Sludge dryer is a kind of new type drying equipment which can effectively dry the sludge to an ideal state and play a role of sterilization. The emission of bacteria can be avoided in the further disposal process. The thermal value of dried sludge is greatly improved. The thermal value of three-ton sludge is similar with the thermal value of one-ton coal. It is a good choice to use the dried sludge for incineration boiler and incineration power generation. Besides, there are a lot of organic matters and plant nutrients. After being dried, the sludge can be directly used as soil improvement agent or compound fertilizer after secondary disposal. Besides, papermaking sludge has been made into bricks, cement and other building materials. With the growing utilization of sludge, it caused less and less pollution to environment. On the contrary, it becomes sustitute for coal and other limited resources. Waste is transferred into useful energy.

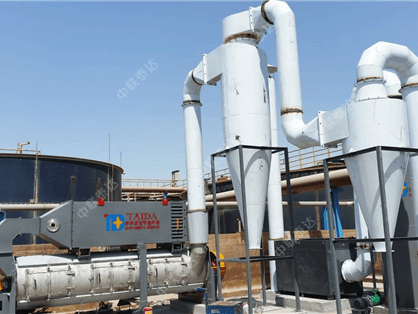

The papermaking sludge dryer developed by zhengzhou taida is a kind of new energy saving product which adopts pump to dry the sludge by hot air circulating cooling. Heat pump dehumidification uses a refrigeration system and heat air by heat and humidity of air cooling and dehumidifying at the same time through the principle of heat pump recovery air moisture condensation latent heating air a device. In short, a heat pump dehumidification is dehumidification (dry and wet) combined with heat pump (energy charge) of the device.

By taking advantage of the principle of latent heat of condensation of water heated air to dry the material, dehumidification drying uses a heat pump refrigeration system to enable objects of drying chamber cooling and dehumidifying humid air through the heat pump at the same time by taking advantage of the principle of latent heat of condensation of water heated air to dry the material. Dehumidifier combines with moisture and heat eliminating pump, which achieves circulating utilization of energy in the process of drying. It is different to conventional hot air drying. Dried air circulates closely in drying chamber and dehumidifier dryer in pump dryer. In traditional hot air dryer, heat air by using heat source and discharge air which has absorbs moisture. The energy utilization rate is very low.

Dehumidification Recuperated regenerator is set in the dehumidification heat pump in order to reduce the temperature of air which enters evaporator and increase the termpereture of air which enters the condensator. Regenerative cycle makes the cooling volume of evaporator used for reducing air temperature (invalid cooling process) and used for increasing cooling volume in heat and moisture eliminating, which makes the best evaporation temperature and best moisture amount eliminated increase in heat pump. The regeneration heat cycle can save about over 30% energy.

中文

中文 English

English Home

Home