Technical introduction

With the development of economy, the demand for oil gas increases annually. Our country has devoted great efforts to the development or land and ocean oil gas. Extensive mining has led to much environmental pollution. There is no a balance between resource development and environmental protection. Especially, our country has transferred its focus to unconventional oil gas fields (shale gas and tight oil). The development method and material used in the process such as oil base mud and hydro fracture contain high pollution, which makes the conflict between development and environmental protection a problem our country needs to solve urgently.

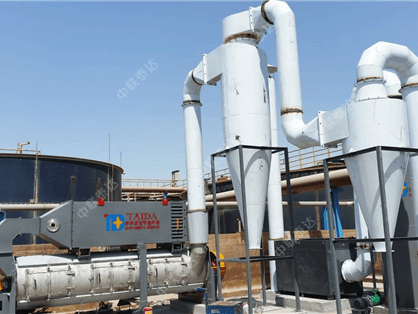

Organic sludge dryer has heat capacity coefficient, high thermal efficiency and multifunction. Its products has no oxidation and deterioration. Wide range of applications, large capacity and easy maintenance.

Advantages

1. This organic sludge dryer holds less energy consumption; insulating layer is set on outer body of dryer;

2. Cost less investment; large heat transfer area; can use different heat media, such as steam, heat conduction oil, hot water and cool water;

3. Can be applied to many kinds of materials;

4. Cause less pollution to environment; cause less dust; small evaporation amount; can adopt closed circuit;

5. Less operation cost; low speed mixture; reasonable structure; less wearing parts; less maintenance cost;

6. Stable operation; materials can get full contact with material granularity;

Working principle

Organic sludge dryer which regards steam as heat source is developed by our company by combining with advantages of foreign drying equipment.

Taida sludge dryer is a kind of dryer which adopts indirect heating and low-speed mixing. It can be operated constantly. It is a kind of energy-saving drying equipment. Steam flows to screw blades through hollow shaft. The design of inner pass way is very special. With clever design, the two shafts can rotate conversely. Extrusion and relaxation actions will be produced between shafts. With the constant mixture and stir of screw blades, the heating area of materials can be updated. Evaporation efficiency gets improved greatly. The area for heat transferring is enlarged in unit effective volume.

This equipment adopts steam as heat media and indirect heat conduction. All amount of heat is used for heating materials. Washing force is produced by the relevant movement between materials granularities and wedge. This washing force can wash out the materials attached on wedge and help keep a clean heat transferring area in the running process. The shape of screw dryer’s shell body is W. Generally, there are two hollow shafts installed in the shell body. There is also an insulation end covering the top, which can not only avoid the leak of materials and dust, but also can collect material solvent vapor. There is a damper installed on the discharge port in order to guarantee the height of material’s level. Then the heat-transfer surface can be fully covered by materials and can fully play its role. Heat-transfer media will flow to jacket and hollow mixing shaft through rotary revolving joint to guarantee best heat-transferring effect.

Technical parameters

|

Item |

Project |

Content |

|

1 |

Equipment model |

XY-9-P |

|

2 |

Suitable raw materials |

Various rubber, plastics, oily sludge and sand |

|

3 |

Structure |

Horizontal rotation |

|

4 |

Size of crack kettle |

Φ1700*8800mm; Φ1700*11000mm |

|

5 |

Daily handling capacity |

20Mt; 25Mt; 35Mt |

|

6 |

Working pressure |

Micro negative pressure |

|

7 |

Power |

60-75Kw/h |

|

8 |

Cooling method |

Cycling water |

|

9 |

Diving mode |

Outer gear ring rotate |

|

10 |

Installation mode |

Integral type |

|

11 |

Noise |

≤85 |

|

12 |

Working mode |

Continuous mode |

|

13 |

(MT)

Total weight |

60 |

中文

中文 English

English Home

Home