Technical introduction

Biodiesel sludge dryer:

Biodiesel industry is a kind of new arising industry. With growing national remediation of gutter oil which retures to table, more and more biodiesel enterprises which regard waste cooking oil as raw materials develop gradually. With the development of biodiesel industry, sewage disposal in this industry gets more and more attention from factories. Sewage in biodiesel has following common problems: high content of sulphuric, low PH value, the highest content of sulfate radical reaches to 20%; high concentration of organic matters (COD); high ratio of B/C; after removal of sulfuric acid, sewage becomes high concentrated organic wastewater; with good biodegradability; biodiesel sludge dryer which is based on dehumidifying heat pump technology has technical advantages in the process of disposing sewage from biodiesel enterprises. This article explains this technology briefly. Hope it can help people in biodiesel industry.

With growing national remediation of gutter oil which retures to table, more and more biodiesel enterprises which regard waste cooking oil as raw materials develop gradually.

Advantages

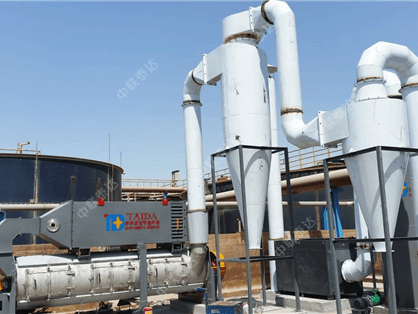

The biodiesel sludge dryer developed by Zhengzhou taida adopts dehumidifying heat pump technology which refers to a device that uses the refrigeration system to use the hot and humid air and recover the latent heat through heat pump principle. Dehumidifying heat pump means a combination of dehumidifying (dehydration) and heat pump (energy recycle). Dehumidifying heat pump sludge dryer is a kind of equipment which aims at materials with high moisture content, high viscosity, high water holding capacity and low thermal value. speicially developed sludge drying equipment holds two-effect and tri-effect patent technology, which makes comprehensive dehumidifying performance ratio reach to over 20%. This technology solves problems such as bad dehumidifying performance and racing problem under hot temperature and low moisture condition. Biodiesel sludge dryer takes advantage of dehumidifying heat pump to dry sludge with hot air circulating and cooling dehumidifying. The traditional sludge thermal drying system provides 90% heating into the exhaust heat loss (water vapor latent heat and sensible heat of hot air); dehydration refers to recycling steam latent heat and damp of air in air emissed. There is no waste heat emissed in the dehydrating process.

The heat pump biodiesel sludge dyer provides hot COP whose thermal value is generally from 3 to 5. Only 1kw electricity powe should be conveyed in this system while 4kw electricity needed in traditional dehydrating system. Heat source comes from air water vapor’s phase change and release of condensation heat atmospheric: when the temperature is 30 minus degree centigrade, the caloric value is 2424kj/kg; when the temperature is 60 degree centigrade, the calorific value is 2355kj/kg; when the temperature is 100 degree centigrade, the caloric value is 2258kj/kg (coal calorific value 18000kj/kg).

Low-temperature sludge drying technology represented by biodiesel sludge dryer represents the development direction of future technology. Low temperature technology is a kind of disposal techology where hot dry air produced from low temperature system circulates in the system to dry sludge. The solid content of sludge can be maintained at 20% after being disposed by plate and frame filter press, bag filter press and centrifugal hydroextractor. After being disposed by biodiesel sludge dryer, the sludge can be dried to dry mud with 90% solid content. Our sludge dryer adopts advanced dehumidifying heat pump technology and can save over 40% energy. About 0.25-kw/h electricity is consumed to split one-ton water from sludge. It can adopt peak electricity mode, which can save energy over 60%. In sludge drying equipment, one-kw/h electricity is consumed for one-kg water. Besides, cold water, medicament and other materials are also needed. The technology can reduce one quarter of the sludge volume. Only electricity is consumed in this process. In addition, the energy consumption is only one thirds of normal drying equipment. There is no need for special uniform distribution of sludge. Also, there is no requirement for moisture content. Only the external temperature is maintained from 10 to 35 degree centigrade, the whole process can run efficiently. The automatic control system of biodiesel sludge dryer can not only improve running efficiency, but also hold good running environment. It is always applied to disposing various sludges from small-medium sewage plants.

Working principle

Technical parameters

Biodiesel sludge dryer—bucket type

|

Model |

JHJ-WNB-200FL |

JHJ-WNB-400FL |

JHJ-WNB-800FL |

|

Water eliminated /24H |

200KG |

400KG |

800KG |

|

Dehydration capacity |

8-13kg/h |

15-23kg/h |

30-46kg/h |

|

Total power |

3.5kw |

6kw |

12kw |

|

Energy consumption |

2.3-3.5kg/ |

2.3-3.5kg/ |

2.3-3.5kg/ |

|

Number of compressor |

1 |

1 |

1 |

|

Specification of bunker |

800*800*750 |

1000*1000*900 |

1200*1200*1100 |

|

Cooling |

Air cooling |

Air cooling |

Air cooling |

|

Cryogen |

R134a |

R134a |

R134a |

|

Power supply |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

|

Drying temperature |

40-55degree centigrade /60-80degree centigrade |

40-55degree centigrade /60-80degree centigrade |

40-55degree centigrade (回风)/60-80degree centigrade (送风) |

|

Control system |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

|

Moisture content of dry material |

10-30% |

10-30% |

10-30% |

|

Overall dimensions |

1650*1150*1500 |

12200*1350*1700 |

2600*1550*2000 |

|

Structure |

Whole set |

|

|

Biodiesel sludge dryer—continous mode chart 1

Biodiesel sludge dryer

|

Model |

JHJ-WNL-1000FL |

JHJ-WNL-2000FL |

JHJ-WNL-4000FL |

JHJ-WNL-6000FL |

|

Water amount eliminated/24H |

1000kg |

2000kg |

4000kg |

6000kg |

|

Water amount eliminated |

42kg |

83kg |

166kg |

249kg |

|

Total power |

14kw |

26kw |

50kw |

74kw |

|

Number of heat pump module |

1 |

1 |

2 |

3 |

|

Number of compressor |

2 |

4 |

8 |

12 |

|

Cooling method |

Wind cooling |

Wind cooling |

Wind cooling |

Wind cooling |

|

Flow amount of cooling water |

// |

// |

// |

// |

|

Cryogen |

R134a |

R134a |

R134a |

R134a |

|

Power supply |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

|

Drying temperature |

48-56degree centigrade/65-80degree centigrade |

48-56degree centigrade /65-80 degree centigrade |

48-56degree centigrade/65-80degree centigrade |

48-56degree centigrade/65-80degree centigrade |

|

Control system |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

|

Wet sludge application |

Moisture content:70 to 85% |

Moisture content:70 to 85% |

Moisture content:70 to 85% |

Moisture content:70 to 85% |

|

Moisture content of dry materials |

Moisture content:10 to 50% (adjustable) |

Moisture content:10 to 50% (adjustable) |

Moisture content:10 to 50% (adjustable) |

Moisture content:10 to 50% (adjustable) |

|

Molding method |

Slitting/granulation |

Slitting/granulation |

Slitting/granulation |

Slitting/granulation |

|

Overall dimension mm |

2435*2190*2420 |

3760*2190*2420 |

6460*2190*2420 |

9160*2190*2420 |

|

Structure |

Whole set |

|

|

|

Printing and dyeing sludge dryer—continuous mode (belt type) chart 2

Printing and dyeing sludge dryer

|

Model |

JHJ-WNL-8000SL/FL |

JHJ-WNL-12000SL/FL |

JHJ-WNL-16000SL/FL |

|

Water amount eliminated/24H |

8000kg |

12000kg |

16000kg |

|

Moisture amount eliminated/H |

333kg |

500kg |

667kg |

|

Total power |

98kw |

138kw |

185kw |

|

Number of heat pump module |

2 |

3 |

4 |

|

Number of compressor |

8 |

12 |

16 |

|

Cooling method |

Water cooling |

Water cooling |

Water cooling |

|

Water amount used for cooling |

4.5CBD/H |

7CBD/H |

9CBD/H |

|

Cryogen |

R134a |

R134a |

R134a |

|

Power supply |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

220V/380V460V3H/50HZ |

|

Drying temperature |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

|

Control system |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

|

Application of wet sludge |

Moisture content: 70% to 85% |

Moisture content: 70% to 85% |

Moisture content: 70% to 85% |

|

Moisture content of dry materials |

Moisture content: 10 to 50% (adjustable) |

Moisture content: 10 to 50% (adjustable) |

Moisture content: 10 to 50% (adjustable) |

|

Molding method |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

|

Overall dimension |

7900*3110*3300 |

11150*3110*3300 |

14400*3110*3300 |

|

Structure |

Assemble |

|

|

Biodiesel sludge dryer—continous mode (belt type) chart 3

|

Model |

JHJ-WNL-20000SL |

JHJ-WNL-24000SL |

JHJ-WNL-28000SL |

JHJ-WNL-32000SL |

JHJ-WNL-36000SL |

JHJ-WNL-40000SL |

|

Water amouont eliminated/24H |

20000kg |

24000kg |

28000kg |

32000kg |

36000kg |

40000kg |

|

Water amount eliminated/H |

833kg |

1000kg |

1167kg |

1333kg |

1500kg |

1667kg |

|

Total power |

230kw |

276kw |

322kw |

368kw |

415kw |

460kw |

|

Number of dehumidifying heat pump |

5 |

6 |

7 |

8 |

9 |

10 |

|

Number of compressor |

20 |

24 |

28 |

32 |

36 |

40 |

|

Cooling method |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

|

Flow amount of cooling water |

11m3/h |

13.5m3/h |

16m3/h |

18m3/h |

20.5m3/h |

23m3/h |

|

Cryogen |

R134a |

R134a |

R134a |

R134a |

R134a |

R134a |

|

Power supply |

220/360/460V |

220/360/460V |

220/360/460V |

220/360/460V |

220/360/460V |

220/360/460V |

|

Drying temperature |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

|

Control system |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

|

Application of wet sludge |

Moisture content 70-83% |

Moisture content 70-83% |

Moisture content 70-83% |

Moisture content 70-83% |

Moisture content 70-83% |

Moisture content 70-83% |

|

Moisture of dry materials |

Adjustable10-50% |

Adjustable10-50% |

Adjustable10-50% |

Adjustable10-50%

|

Adjustable10-50% |

Adjustable10-50% |

|

Molding method |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

|

Overall dimension |

17650*3110*3300 |

209000*3110*3300 |

24150*3110*3300 |

27400*3110*3300 |

30650*3110*3300 |

33900*3110*3300 |

|

Structure |

Assemble |

Assemble |

Assemble |

Assemble |

Assemble |

Assemble |

Mutil-la

yer printing and dyeing sludge dryer—continous mode (belt)

|

Model |

JHJ-WNL-40000SLF |

JHJ-WNL-48000SLF |

JHJ-WNL-56000SLF |

JHJ-WNL-64000SLF |

JHJ-WNL-72000SLF |

JHJ-WNL-80000SLF |

|

Water amouont eliminated/24H |

40000kg |

48000kg |

56000kg |

64000kg |

72000kg |

80000kg |

|

Water amount eliminated/H |

1666kg |

2000kg |

2334kg |

2666kg |

3000kg |

3334kg |

|

Total power |

460kw |

552kw |

644kw |

736kw |

830kw |

920kw |

|

Number of dehumidifying heat pump |

10 |

12 |

14 |

16 |

18 |

20 |

|

Number of compressor |

40 |

48 |

56 |

64 |

72 |

80 |

|

Cooling method |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

Water cooling |

|

Flow amount of cooling water |

23m3/h |

27m3/h |

32m3/h |

36m3/h |

41m3/h |

46m3/h |

|

Cryogen |

R134a |

R134a |

R134a |

R134a |

R134a |

R134a |

|

Power supply |

220/360/460V |

220/360/460V |

220/360/460V |

220/360/460V |

220/360/460V |

220/360/460V |

|

Drying temperature |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade)/65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

48-56 degree centigrade /65-80 degree centigrade |

|

Control system |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

Touch screen, PLC |

|

Application of wet sludge |

Moisture content: 70% to 83% |

Moisture content: 70% to 83% |

Moisture content: 70% to 83% |

Moisture content: 70% to 83% |

Moisture content: 70% to 83% |

Moisture content: 70% to 83% |

|

Moisture content of dry materials |

Adjustable 10-50% |

Adjustable10-50% |

Adjustable10-50% |

Adjustable10-50% |

Adjustable10-50% |

Adjustable10-50% |

|

Molding method |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

Slitting/ granulating |

|

Overall dimension |

17650*3110*6600 |

209000*3110*6600 |

24150*3110*6600 |

27400*3110*6600 |

30650*3110*6600 |

33900*3110*6600 |

|

Structure |

Assemble |

|

|

|

|

|

The energy consumption of our sludge dryer is one third of common drying method. In common dryer, l-kw electricity is consumed to evaporate 1-kg water. Low temperature sludge drying system adopts energy conversion technology with low energy consumption. Without considering outer heat source, 0.33 to 0.4 kw/h electricity is needed to evaporate 1-kg water for standard products. Special plate-fin type regenerative cycle, double-effect heat pump dehumidifier and tri-effect heat pump dehumidifier are advanced technology at home and abroad. These technologies not only overcome the bottlenecks of traditional refrigeneration and dehumidfication, but also expand applications of refrigeneration and dehumidification technologies.

Generally, the heat pump dehumidifier used by biodiesel sludge dryer adopts multi-layer belt conveying device matching with pellet press. It can produce sludge granular fertilizer constantly. Taking heat pump dehumification drying device which disposes 10-cubic meter sludge as example, equipment only covers a 60-square meter area; when the amount of sludge disposed increases, users can assemble several sets of drying devices together, which will expand production capacity.

中文

中文 English

English Home

Home