Taeda low temperature exhaust heat sludge drying system (hereafter called WRC system) can make use of boiler exhaust heat to dry dewatered sludge with 85% moisture content. It holds large capacity and good drying effect. We can also customize according to customers’ demands. Because it can make use of 100-degree low temperature hot air, it is also suitable for drying heat-sensitive materials.

Suitable for drying: sludge, white mud, printing and dyeing sludge, municipal sludge, sewage sludge, activated sludge, electroplating sludge, papermaking, oil field sludge, chemical sludge, mineral sludge, gypsum, peat, black rice, pigs Cow and chicken manure, wood chips, wood chips, sawdust, vinyl chloride, ABS resin, copper powder, iron powder, nickel powder, lead powder and other non-sticky mineral powder, coal powder, coke powder and ammonium sulfate, nitric acid Dehydration and drying of high-humidity materials such as ammonium, urea, calcium-magnesium phosphate fertilizers, organic and inorganic compounds in mud, powder, and flakes, and other heat-sensitive materials.

Typical advantages:

■New design can prevent sticking and guarantees large capacity. WRC system can dry materials with 85% moisture content into qualified final products one time. Aimed at easy-caking feature of sludge during drying process, we improve material plate structure of single drum dryer and adopts combined self-cleaning device, which greatly expands application range of single drum dryer. WRC can be used to dry sludge and other various sticky materials.

■Low hot air temperature makes it adapt to wide range moisture content. It can use boiler exhaust heat as heat source to dry dewatered sludge with 85% moisture content. It can also apply 100-degree hot air to finish drying work.

1.Large dealing capacity, high thermal efficiency; can use boiler exhaust heat, which makes WRC system cost effective and low running cost.

2.Adopt computer for automatic control. Drying temperature and drying period can be automatically configured according to different drying demands. Both labor force and material cost can be saved and working efficiency is improved.

3.New internal structure strengthens cleaning and heat conduction function for scattered materials and avoids wall sticking phenomenon. It can adapt to various material and different moisture range. Configuring pin column replaceable gear for transmission part, which can replace traditional casting steel gear and save investment cost. Meanwhile, maintenance cost and time are greatly saved.

4.After adjustment by riding wheel, force born by catch wheel is greatly reduced. Correspondingly, service life for catch/riding wheel and riding wheel are extended. Production cost is decreased and drying effect is improved.

As core equipment in low temperature rotary drum sludge drying system, we can configure either one-step drying or multi-class dryer in series for customers. Sludge with lower than 85% moisture can enter WRC drying system directly and hot air with lower than 100 degrees can be applied as heat source.

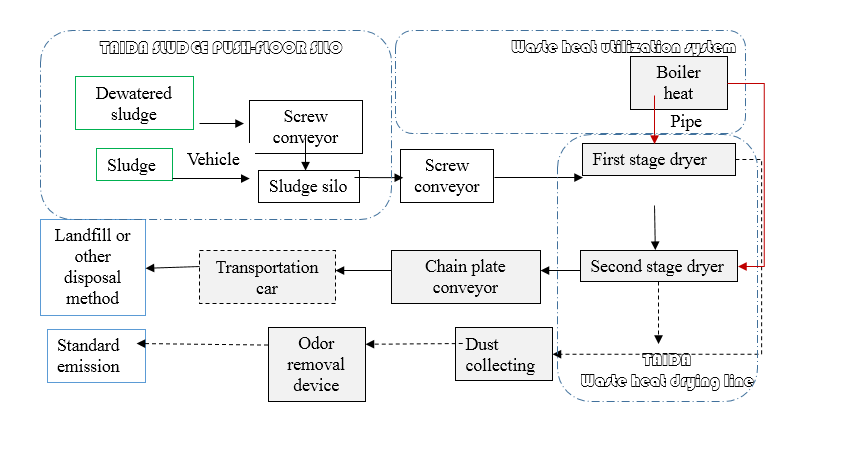

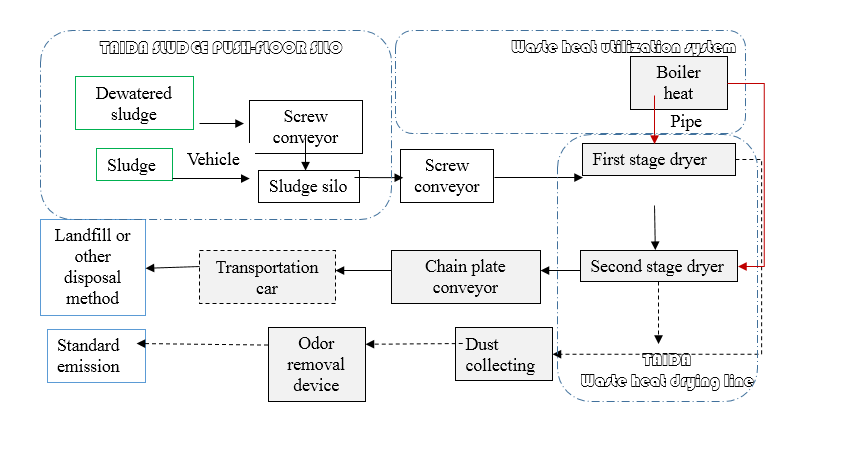

Working principle is shown as below:

|

Input capacity |

Power/kw |

Technical specification |

备注 |

|

Running power |

Installed power |

Model |

Dimension |

|

10t/d |

48 |

60 |

WRC-1 |

φ1.8 |

提供全流程、全系统技术及产品服务

(技术服务费用单独核算) |

|

20t/d |

55 |

70 |

WRC-2 |

φ2.4 |

|

50t/d |

65 |

80 |

WRC-3 |

φ3.2 |

|

100t/d |

76 |

95 |

WRC-4 |

φ4.2 |

Notes; Technical parameters are subject to change without prior notice.

中文

中文 English

English Home

Home