Technical introduction

Product introduction:

Brief introduction

Double-cone mixer mainly aims at the mixture of powder and powder. It is rarely applied to batch mixing. For those products with low request of product uniformity and no dead angle, we generally adopt equipment designed with rotary drum. According to the the shape of drum, rotary methods, the distribution way of inner blades, the mixer can be divided into several kinds, double-cone mixer, V-shape mixer and single drum type. There are several processes in the whole production line such as feeding after stopping, mixing while start-up and discharging after stoping. This equipment can cooperate with vacumm feeder.

Applications:

Food, medicine, coffee, milk powder, instat noodle, eight-tresures congee, ham sausage, walnut powder, pepper powder, flour, preservatives, preservatives, flavor spices, monosodium glutamate and etc.

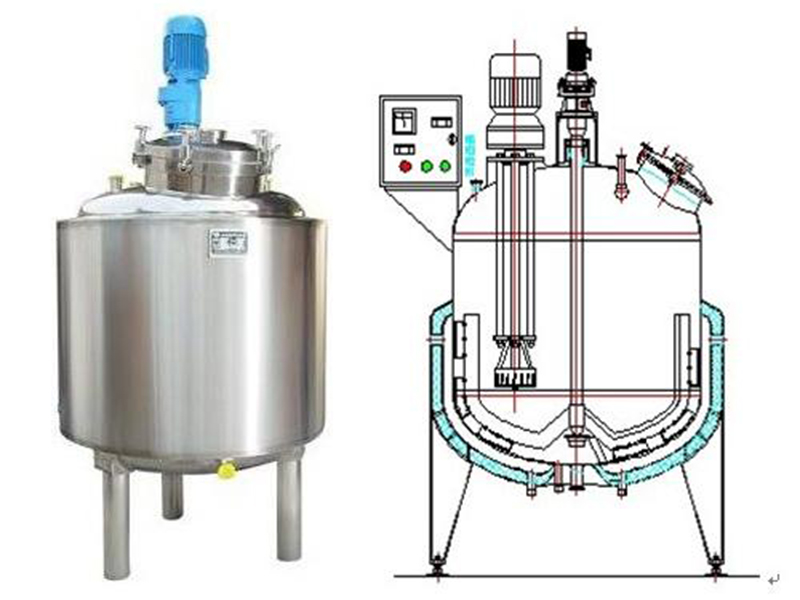

Appearance chart

Advantages

1. Compact structure, simple operation; simple and clean; stably running; no noise;

2. Can be applied to many kinds of mixture of materials; products with high uniformity;

3. Can adopt vacumm feed and butterfly outlet;

4. There is overload protection for motor and speed meter controls the uploading position after shutdown the machine;

Working principle

Double-cone mixer is composed of rotary drum, supports and drive part.

Rotary drum adopts double-cone design or other relavant forms; at the same time, the design of drum adopts different forms of blades. Materials are elevated, scattered and mixed in the drum in order to realize rapid mixture effect. Finally, even mixing will be achieved. In the whole process, drum will turn continously. All materials in drum will move and there is no dead angle.

Materials are supposed to have fluidity and materials with mucosity can not be scattered.

In the process of mixing, operator must stop the machine and add materials. The production must be carried out batchly. The production efficiency is not high.

Technical parameters

设备型号

Equipmetn model |

设备容积

(L)

Equipment voume |

生产容积

(L/Batch)

Production volume |

混合量

(Kg/Batch)

Mixing amount |

功率

(Kw)

Power |

主轴转速

(R/min)

Rotary speed of main shaft |

外形尺寸

(mm)

Overall dimensions |

设备重量

Weight of equipmetn

(Kg) |

|

MSZH-100 |

100L |

30~50 |

<100 |

1.1 |

15 |

1500*600*1500 |

240 |

|

MSZH-200 |

200L |

50~100 |

<150 |

1.5 |

15 |

1750*700*1700 |

300 |

|

MSZH-500 |

500L |

150~250 |

<300 |

2.2 |

15 |

4200*1650*1560 |

650 |

|

MSZH-1000 |

1000L |

300~500 |

<600 |

3 |

12 |

4400*1850*1850 |

900 |

|

MSZH-1500 |

1500L |

300~800 |

<800 |

4 |

12 |

4500*1850*2000 |

980 |

|

MSZH-2000 |

2000L |

500~1000 |

<1000 |

5.5 |

12 |

5400*2050*2250 |

1600 |

|

MSZH-3000 |

3000L |

500~1500 |

<1500 |

7.5 |

9 |

6550*2350*2700 |

1800 |

|

MSZH-4000 |

4000L |

1000~2000 |

<2000 |

11 |

9 |

6800*2500*3000 |

2200 |

Notes:

1. The data in the chart is got ba

sed on the media whose proportion is . Selection should be based on the mesh of materials, proportion and other parameters;

2. If there are following working conditions, such as high temperature, high pressure, inflammable, explosive and corrosive situations, customers must provide specific datas for our correct selections;

3. If there is any change of the data in this chart, we will not provide prior notice. Correct parameters are subject to real materials;

This chart only contains some part of our equipment. If you want to know more about our information, please contact us.

中文

中文 English

English Home

Home