landfill technology of sludge solidification and stabilization

Author: Taida machine Release time:2016-08-18

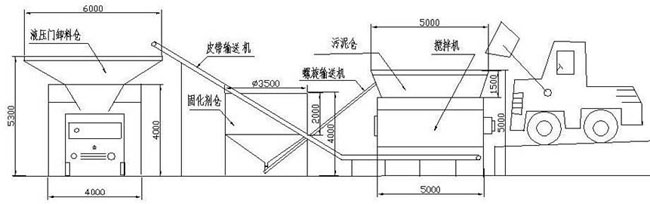

Reading guidance:80% moisture content of sludge filter press into the sludge storage. At the bottom of the storage bin is spiral conveying device, deliver the sludge to bi-axial mixing device at the front end of the, a

80% moisture content of sludge filter press into the sludge storage. At the bottom of the storage bin is spiral conveying device, deliver the sludge to bi-axial mixing device at the front end of the, also will curing material three components a, B, C by quantitative conveying device are sent to the automatic mixing device, after mixing evenly solidified material by conveying device together with transport to bi-axial mixing device at the front end of the, discharge sludge moisture and curing materials in bi-axial mixer on time quantitative mixing crushed, by a belt conveying device sent to curing sludge stabilization storage to be shipped after 72 hours of sludge strength 50kPa, usable for sub-grade, greening, brick, covering soil, ecological restoration.

1. Working principle

Sludge solidification and stabilization technology for sewage sludge moisture content 75% to 85%), by adding unique solidification / stabilization material of sludge were modified, the physical properties of sludge and chemical properties tend to be stable. Curing is refers to by the strength improvement of sludge, reducing the permeability to change the physical properties of sludge process. Stability is refers to the morphological transformation of sludge containing heavy metal pollutants, constructed within a closed system and changes of chemical properties of the sludge.

2. Sludge in sewage plants

Sludge is a kind of mud like substance which is produced in the sewage disposal process; its density is about 1.0; its basic character is following:

1. Working principle

Sludge solidification and stabilization technology for sewage sludge moisture content 75% to 85%), by adding unique solidification / stabilization material of sludge were modified, the physical properties of sludge and chemical properties tend to be stable. Curing is refers to by the strength improvement of sludge, reducing the permeability to change the physical properties of sludge process. Stability is refers to the morphological transformation of sludge containing heavy metal pollutants, constructed within a closed system and changes of chemical properties of the sludge.

2. Sludge in sewage plants

Sludge is a kind of mud like substance which is produced in the sewage disposal process; its density is about 1.0; its basic character is following:

Chart 1 index of sludge in different areas

A. Moisture content of sludge

Free water: The presence of water in the pores of the solid particles, generally in the mixing process of the mixture is solidified material absorption and binding, in compression, extrusion will precipitate.

Absorption water: absorbed at the surface of particles by solid particles;

Cell bound water: exist in solid particles and cell membrane

B. Solid substances in sludge: divided into organic matters and inorganic matters

Inorganic matters: Mainly inorganic minerals, as well as a variety of forms of heavy metals and nutrients.

Organic matters: Microbial residues, biological membranes, fibrous materials.

C. Fluidity of sludge: The sludge is not disturbed in a jelly like, paste, can not be enough accumulation, when handling will drop sprinkle. Dehydration can be changed into a dry block, broken slag, sometimes able to plug the pipe, pore.

D. Impurities in sludge: In dehydration, handling process will be brick, stone, with branches.

E. Odors: Fresh sludge after fermentation will stink, mud storage, transport devices are easy to produce odor.

1. Add materials

Generally speaking, there are three kinds of materials which can be added;

A. solidified material A

Dry powder, adding amount of 5~20%, continuous, quantitative add.

B. solidified material B

Dry powder, the addition amount of 2~10%, continuous, long-term exposure to air. Add quantitative storage will produce heat and water, should be closed.

C. solidified material C

Dry powder, add the amount of 5~20% between, continuous, quantitative add. Long-term storage will be affected with damp, agglomerate.

2. Main process types

According to the different needs of users, the treatment process can be divided into sewage treatment plant, handling type, centralized treatment.

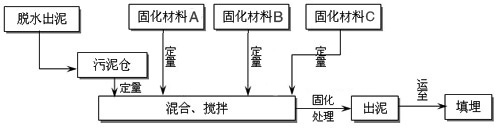

A. Factory processing type

In sewage plant dehydration workshop back end interface. After the sludge dehydration directly into the sludge solidification / stabilization treatment device, in the device after treatment of mixed loading were transported to landfill site. Technological characteristics should be is a small, small size, covers an area of small, the ability to deal with 50 to 150t/d, according to work every day for 8 hours.

Free water: The presence of water in the pores of the solid particles, generally in the mixing process of the mixture is solidified material absorption and binding, in compression, extrusion will precipitate.

Absorption water: absorbed at the surface of particles by solid particles;

Cell bound water: exist in solid particles and cell membrane

B. Solid substances in sludge: divided into organic matters and inorganic matters

Inorganic matters: Mainly inorganic minerals, as well as a variety of forms of heavy metals and nutrients.

Organic matters: Microbial residues, biological membranes, fibrous materials.

C. Fluidity of sludge: The sludge is not disturbed in a jelly like, paste, can not be enough accumulation, when handling will drop sprinkle. Dehydration can be changed into a dry block, broken slag, sometimes able to plug the pipe, pore.

D. Impurities in sludge: In dehydration, handling process will be brick, stone, with branches.

E. Odors: Fresh sludge after fermentation will stink, mud storage, transport devices are easy to produce odor.

1. Add materials

Generally speaking, there are three kinds of materials which can be added;

A. solidified material A

Dry powder, adding amount of 5~20%, continuous, quantitative add.

B. solidified material B

Dry powder, the addition amount of 2~10%, continuous, long-term exposure to air. Add quantitative storage will produce heat and water, should be closed.

C. solidified material C

Dry powder, add the amount of 5~20% between, continuous, quantitative add. Long-term storage will be affected with damp, agglomerate.

2. Main process types

According to the different needs of users, the treatment process can be divided into sewage treatment plant, handling type, centralized treatment.

A. Factory processing type

In sewage plant dehydration workshop back end interface. After the sludge dehydration directly into the sludge solidification / stabilization treatment device, in the device after treatment of mixed loading were transported to landfill site. Technological characteristics should be is a small, small size, covers an area of small, the ability to deal with 50 to 150t/d, according to work every day for 8 hours.

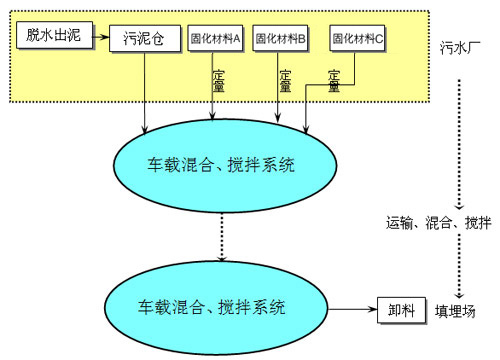

B. Transport handling type

The process is a vehicle type processing device, in sewage plant dehydration workshop back-end directly sludge into the on-board processing device, and add the needs of a variety of materials, were mixed in the transportation process, stirring, transported to the site after unloading. Technical characteristics should is easy to move, sealing and no smell, no occupation. At the same time to consider the construction of feeding system in waste water treatment plant. Ability to deal with 10 to 20t/ car.

The process is a vehicle type processing device, in sewage plant dehydration workshop back-end directly sludge into the on-board processing device, and add the needs of a variety of materials, were mixed in the transportation process, stirring, transported to the site after unloading. Technical characteristics should is easy to move, sealing and no smell, no occupation. At the same time to consider the construction of feeding system in waste water treatment plant. Ability to deal with 10 to 20t/ car.

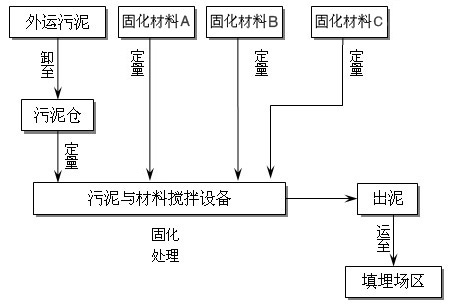

C. Centralized treatment type

Sludge is transported to landfill site for centralized treatment process. Sludge by transport vehicles transported to the processing field in the processing field of feeding system and mixing system for processing. Process characteristics should is large, processing capacity should be in 300 to 900t/d, working hours per day 10 hours.

Sludge is transported to landfill site for centralized treatment process. Sludge by transport vehicles transported to the processing field in the processing field of feeding system and mixing system for processing. Process characteristics should is large, processing capacity should be in 300 to 900t/d, working hours per day 10 hours.

1. Process requests

In order to ensure the stabilization of sludge solidification technology, processing equipment must have the following technical performance:

A. processing uniformity: mixed treated mud not being able to see a significant increase in material.

B. the degree of disturbance: after stirring does not appear a large number of cell water precipitation stirred dilute phenomenon.

C. precise control: the mud and the additive can realize the full automatic control, the control precision of the adding quantity is less than 1%.

D. to achieve full closed treatment, to avoid odor leakage.

E. after 72 hours treatment of sludge strength 50kpa.

F. maintenance and repair of equipment.

6. Equipment introduction

The device is to achieve sludge solidification and stabilization and specialized research developed a patented device, applicable to all types of sewage treatment plant (station) the sludge is discharged, silt in rivers and lakes and other industry generated sludge. Sludge after treatment properties of stability, non-toxic harmless, ways of resource utilization.

In order to ensure the stabilization of sludge solidification technology, processing equipment must have the following technical performance:

A. processing uniformity: mixed treated mud not being able to see a significant increase in material.

B. the degree of disturbance: after stirring does not appear a large number of cell water precipitation stirred dilute phenomenon.

C. precise control: the mud and the additive can realize the full automatic control, the control precision of the adding quantity is less than 1%.

D. to achieve full closed treatment, to avoid odor leakage.

E. after 72 hours treatment of sludge strength 50kpa.

F. maintenance and repair of equipment.

6. Equipment introduction

The device is to achieve sludge solidification and stabilization and specialized research developed a patented device, applicable to all types of sewage treatment plant (station) the sludge is discharged, silt in rivers and lakes and other industry generated sludge. Sludge after treatment properties of stability, non-toxic harmless, ways of resource utilization.

:Contrast between common conveying devices for sludge :Discuss about the research of sludge solidification disposal in municipal sewage disposal plants

Relevant news

- 2016-01-12OSC-II Model Sludge Dryer Deliv

- 2016-01-1215T/Day Aerobic Dynamic Ferment

- 2016-01-12Matters Should Be Paid Attentio

- 2016-01-12Methods exploration of chemical

- 2016-01-12Analysis of circulating fluid b

Industry trends

- 2016-01-12Comparison Between Different Sl

- 2016-01-12Adding Calcium and Stable Dispo

- 2016-01-12Sludge Treatment: Methods for S

- 2016-01-12Use Dyeing Sludge As Resource

- 2016-01-12Current situation of sludge dis

Hot spots

Hot-sale products

- Leather Industry Sludge Drying

Production Capacity:1-2200t/h

- Welding Plating Sludge Drying S

Production Capacity:1-2200t/h

- Municipal Sludge Drying Solutio

Production Capacity:1-2200t/h

- Manure Sludge Drying Solution

Production Capacity:1-2200t/h

中文

中文 English

English Home

Home