Low-temperature heat drying disposal process for sludge

Author: Taida machine Release time:2016-08-18

Reading guidance:Working principle: Sludge water rate is high because of the activated sludge in the attachment and internal biological water is difficult to be prolapse. Sludge thermal drying process is using low temp

Working principle:

Sludge water rate is high because of the activated sludge in the attachment and internal biological water is difficult to be prolapse. Sludge thermal drying process is using low temperature and medium pressure heat indirect dry sludge and by thermal conditioning process activated sludge biological cell wall breaking and precipitation of biological internal water and capillary water, the attached water, activity of killing virus and bacteria and other harmful substances in the process. The process can be to sludge drying to moisture content below 30%.

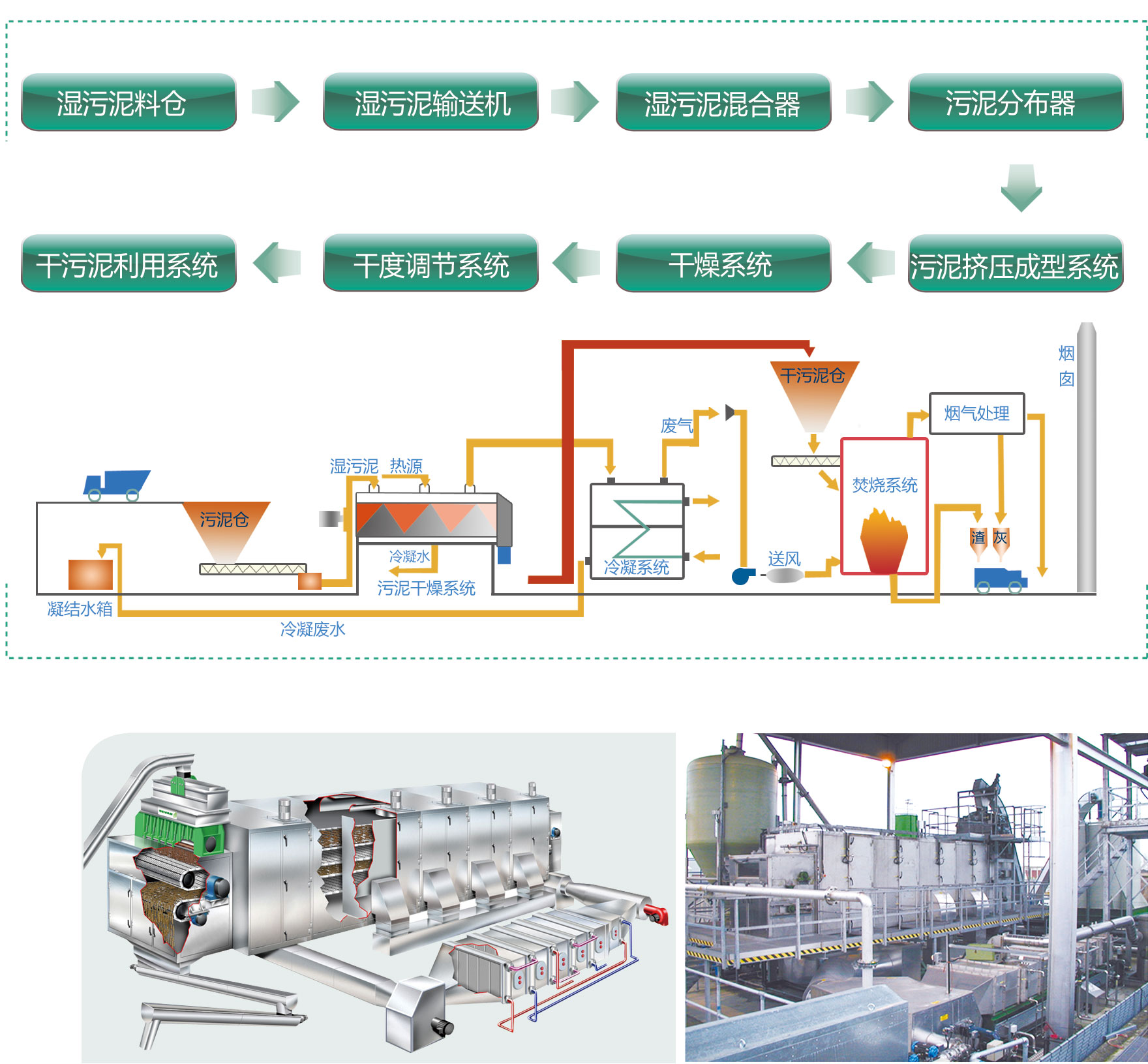

Process flow of heat drying for sludge

Features of low-temperature heat drying technology

Specially designed for sludge drying process;

Low dust load;

The maximum surface area can be achieved through the formation of the particles by the sludge particles;

low cost for maintenance; simple design;

Low gas emission; high efficiency of gas circulating

Low drying temperature reduces load while low-temperature stream condensation;

Can make use of various heat sources; Comprehensive and lasting sterilization, the system can maintain a long time after the sterilization temperature, can effectively kill bacteria;

Sludge disposal and utilization of safe, dry matter content is high, the sludge can be directly buried, incineration, collaborative disposal and utilization;

Through the closed heat insulation and internal heat efficient circulation, to ensure low energy consumption;

Matching investment is low, the system equipment structure design is compact and scientific, and the investment is saved;

Simple operation and running;

Sludge disposal

Main disposal methods for sludge are landfill, incineration, direct incineration and building materials.

Landfill

Landfill is a kind of traditional sludge disposal method. after disposal, sludge will be dumped into garbage ground and landfill site. Landfill disposal of sludge treatment to lower, general volume reduction can be stable. But due to the landfill needs to occupy land and large transportation costs, transverse shear strength of sludge and infiltration filtrate discharge were requirements, China has restricted not by inorganic chemical treatment of the sludge landfill, the proportion of sludge landfill disposal will decrease rapidly.

Incineration

Incineration is the most thorough treatment and disposal methods, refers to the dehydration of sludge drying and incinerating. Its biggest advantage is can be rapidly and to a greater extent realize sludge reduction, sludge storage equipment, can meet the requirements of more and more strict environment. It can also be used in treatment and disposal is not suitable for resource utilization of sludge. The sludge incineration needed infrastructure investment and operation cost are high.

Sludge power plant Co incineration

The coal-fired power plant sludge mixed with coal burning. In order to improve the economy of sludge disposal, sludge moisture rate should be below 50%, achieve the self-sustaining mixed combustion.

Domestic sludge are incinerated

sludge is sent to incineration equipment directly; or incinerated with as a mixture;

Co incineration of sludge by cement kiln

Sludge into the cement kiln calcining partly in place of clay as raw material, cement, to achieve the purpose of sludge disposal coordination. After drying the sludge in the kiln tail smoke chamber or ascending flue, pre-decomposition furnace feeding position.

When the sludge is disposed by the cement kiln system, the content of sulfur, chlorine and other harmful elements such as chlorine and alkali should be controlled, and the equivalent ratio of the sulfur base element is controlled in 0.6% to 1.0%, and the chlorine element should be controlled to 0.03% to 0.04%.

Applied to building materials

sludge can be used for building materials; after being incinerated, final products can be applied to construction project and roadbed materials.

Sludge water rate is high because of the activated sludge in the attachment and internal biological water is difficult to be prolapse. Sludge thermal drying process is using low temperature and medium pressure heat indirect dry sludge and by thermal conditioning process activated sludge biological cell wall breaking and precipitation of biological internal water and capillary water, the attached water, activity of killing virus and bacteria and other harmful substances in the process. The process can be to sludge drying to moisture content below 30%.

Process flow of heat drying for sludge

Features of low-temperature heat drying technology

Specially designed for sludge drying process;

Low dust load;

The maximum surface area can be achieved through the formation of the particles by the sludge particles;

low cost for maintenance; simple design;

Low gas emission; high efficiency of gas circulating

Low drying temperature reduces load while low-temperature stream condensation;

Can make use of various heat sources; Comprehensive and lasting sterilization, the system can maintain a long time after the sterilization temperature, can effectively kill bacteria;

Sludge disposal and utilization of safe, dry matter content is high, the sludge can be directly buried, incineration, collaborative disposal and utilization;

Through the closed heat insulation and internal heat efficient circulation, to ensure low energy consumption;

Matching investment is low, the system equipment structure design is compact and scientific, and the investment is saved;

Simple operation and running;

Sludge disposal

Main disposal methods for sludge are landfill, incineration, direct incineration and building materials.

Landfill

Landfill is a kind of traditional sludge disposal method. after disposal, sludge will be dumped into garbage ground and landfill site. Landfill disposal of sludge treatment to lower, general volume reduction can be stable. But due to the landfill needs to occupy land and large transportation costs, transverse shear strength of sludge and infiltration filtrate discharge were requirements, China has restricted not by inorganic chemical treatment of the sludge landfill, the proportion of sludge landfill disposal will decrease rapidly.

Incineration

Incineration is the most thorough treatment and disposal methods, refers to the dehydration of sludge drying and incinerating. Its biggest advantage is can be rapidly and to a greater extent realize sludge reduction, sludge storage equipment, can meet the requirements of more and more strict environment. It can also be used in treatment and disposal is not suitable for resource utilization of sludge. The sludge incineration needed infrastructure investment and operation cost are high.

Sludge power plant Co incineration

The coal-fired power plant sludge mixed with coal burning. In order to improve the economy of sludge disposal, sludge moisture rate should be below 50%, achieve the self-sustaining mixed combustion.

Domestic sludge are incinerated

sludge is sent to incineration equipment directly; or incinerated with as a mixture;

Co incineration of sludge by cement kiln

Sludge into the cement kiln calcining partly in place of clay as raw material, cement, to achieve the purpose of sludge disposal coordination. After drying the sludge in the kiln tail smoke chamber or ascending flue, pre-decomposition furnace feeding position.

When the sludge is disposed by the cement kiln system, the content of sulfur, chlorine and other harmful elements such as chlorine and alkali should be controlled, and the equivalent ratio of the sulfur base element is controlled in 0.6% to 1.0%, and the chlorine element should be controlled to 0.03% to 0.04%.

Applied to building materials

sludge can be used for building materials; after being incinerated, final products can be applied to construction project and roadbed materials.

Relevant news

- 2016-01-12OSC-II Model Sludge Dryer Deliv

- 2016-01-1215T/Day Aerobic Dynamic Ferment

- 2016-01-12Matters Should Be Paid Attentio

- 2016-01-12Methods exploration of chemical

- 2016-01-12Analysis of circulating fluid b

Industry trends

- 2016-01-12Comparison Between Different Sl

- 2016-01-12Adding Calcium and Stable Dispo

- 2016-01-12Sludge Treatment: Methods for S

- 2016-01-12Use Dyeing Sludge As Resource

- 2016-01-12Current situation of sludge dis

Hot spots

Hot-sale products

- Leather Industry Sludge Drying

Production Capacity:1-2200t/h

- Welding Plating Sludge Drying S

Production Capacity:1-2200t/h

- Municipal Sludge Drying Solutio

Production Capacity:1-2200t/h

- Manure Sludge Drying Solution

Production Capacity:1-2200t/h

中文

中文 English

English Home

Home